- Offices Time:24 Hours Online

- Email:[email protected]

- WhatsApp:+8618339938759

Posted on November 8, 2022

What types of high voltage cables are there?

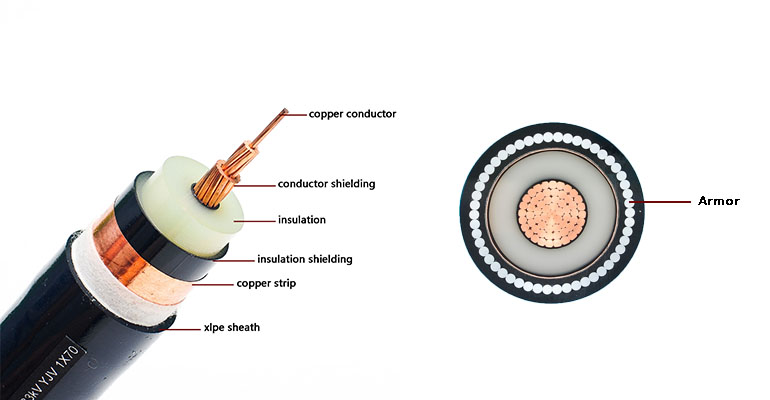

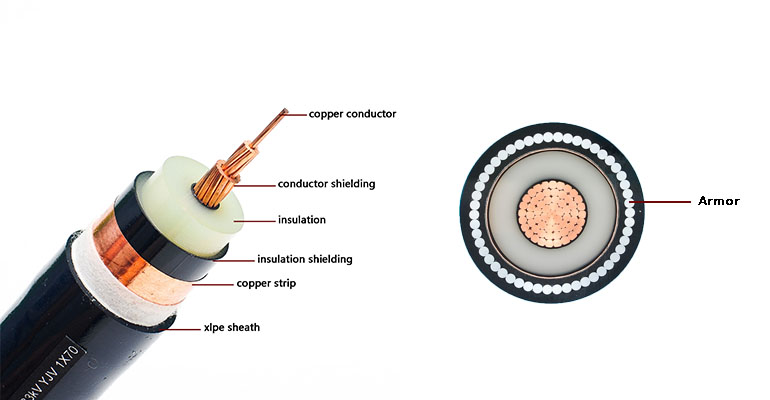

We know that high-voltage cable is a kind of power cable, which refers to the power cable used to transmit 10KV-35KV, mainly used in the main road of power transmission. High-voltage cables are the most commonly used cable types. The components include conductor, inner shield, insulation, outer shield, copper tape, filler, inner sheath, armor, and outer sheath. Common high-voltage cables include ordinary high-voltage cables and flame-retardant high-voltage cables, fire-resistant high-voltage cables, steel tape armored high-voltage cables, thick armored high-voltage cables, thin steel wire armored high-voltage cables, and single-core armored high-voltage cables. Flame retardant high-voltage cables are especially suitable for fixed laying occasions with special flame retardant requirements, such as power stations, nuclear power plants, petrochemicals, urban rail transit, and high-rise buildings.

1.Common specifications and model descriptions of high-voltage cables

(1) XLPE insulated power cable (ordinary high voltage cable) 0.6/1KV 6/6KV 8.7/10KV 8.7/15KV 26/35KV.

Specifications and models: 35KV and below YJV YJLV YJV22 YJLV22 YJV32 YJLV32.

(2) Flame retardant XLPE insulated power cable (flame retardant high voltage cable) 0.6/1KV 6/6KV 8.7/10KV 8.7/15KV 26/35KV.

Specifications and models: 35KV and below ZR-YJV ZR-YJLV ZR-YJV22 ZR-YJLV22 ZR-YJV32 ZR-YJLV32.

(3) Fire-resistant XLPE insulated power cable (fire-resistant high-voltage cable) 0.6/1KV 6/6KV 8.7/10KV 8.7/15KV 26/35KV.

Specifications and models: 35KV and below NH-YJV NH-YJLV NH-YJV22 NH-YJLV22 NH-YJV32 NH-YJLV32.

For high-voltage cables, we can mainly see wires on utility poles and cables in underground pipes. The common laying methods of high-voltage cables are buried, pipeline, tunnel and overhead. For different laying methods, the selection of high-voltage cables also has certain requirements. Due to the difference in our needs, we will choose between low-voltage cables and high-voltage cables. In the process of understanding, we will find the differences between low-voltage cables and high-voltage cables. We introduced low-voltage cables to you before, so now I will briefly introduce them to you. Popularize some professional knowledge of high-voltage cable laying and selection!

2.Laying method of high-voltage cables

(1) Buried

It refers to laying high-voltage cables on the ground, and choosing buried laying provides higher protection to the cable itself, and is suitable for using armored wires and cables with an outer protective layer; for some unstable geological environment standards such as swamps, quicksand, etc., also Optional stainless steel wire armoured wires and cables.

(2) Pipeline

Refers to laying high-voltage cables in pipes of prefabricated components. This laying method is very easy to cause the cable to overheat, resulting in power engineering loss and capacitance reduction, so it is more appropriate to choose a plastic protective shell cable or a bare armored cable.

(3) Tunnel construction type

It refers to the laying of high-voltage cables on cable trays or brackets during the construction of cable tunnels. This type of laying method is mostly used in local areas and has the characteristics of good heat dissipation and maintenance. However, the cable has higher requirements on the flame retardant grade, and is suitable for the application of bare armored cable or PVC wire protective shell cable.

(4) Empty frame

It refers to the connection and laying of high-voltage cables according to the columns (telephone poles). This laying method is suitable for areas with flat terrain and less undulations, but this method makes the cable completely exposed to outdoor and indoor spaces, and is very susceptible to environmental factors and external forces. Choose a cable with an outer coating or an all-plastic cable appropriate.

High-voltage cable selection considerations are quite complex because there are quite a few types. As for the cable itself, high-voltage cables can be divided into aluminum-core cables and copper-core cables according to their materials. For those areas with complex environmental conditions and special requirements, it is more reliable to use copper-core cables in terms of quality and safety.

Post categories

Most Popular Posts

-

The 136th Canton Fair welcomes you to participate!

October 12, 2024 -

High temperature cable introduction

July 26, 2024 -

Kenya Power and Energy Exhibition 2024

June 11, 2024 -

Introduction of rubber sheathed cable

June 5, 2024