- Offices Time:24 Hours Online

- Email:[email protected]

- WhatsApp:+8618339938759

Posted on February 22, 2023

What is concentric cable?

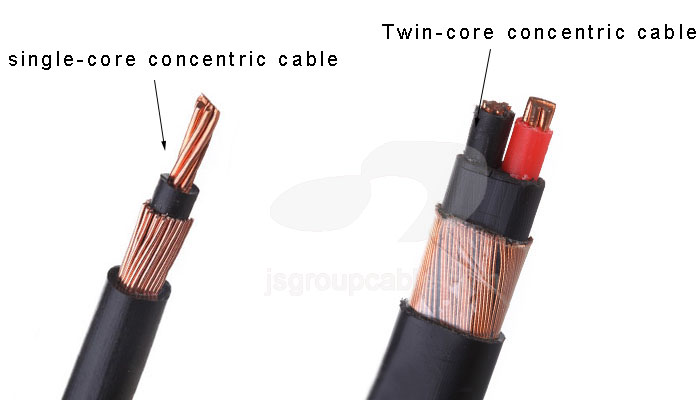

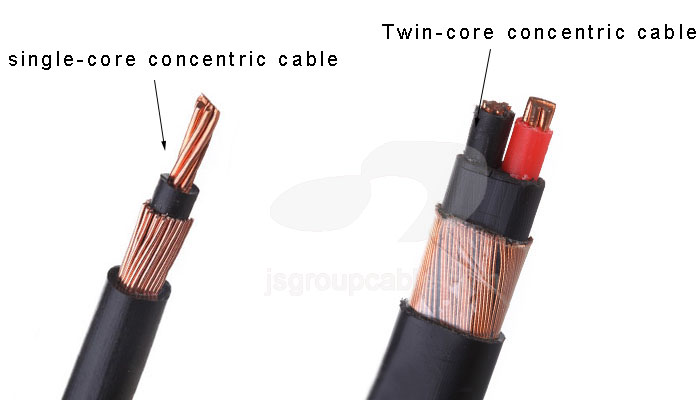

Concentric cable is a type of electrical cable that consists of a central conductor surrounded by one or more layers of concentrically arranged conductors. The central conductor is usually a solid or stranded copper wire, while the outer conductors are typically made of copper or aluminum strands.Concentric cables are commonly used for power transmission and distribution in overhead lines and underground cables.

One common type of concentric cable is the triplex cable, which consists of three conductors: a neutral wire surrounded by two hot wires. Triplex cables are commonly used for residential service drops and are often seen hanging from utility poles.

The structure of concentric cable:

The structure of concentric cable typically consists of a central conductor, one or more layers of insulation, and one or more layers of concentrically arranged conductors.

The central conductor is usually a solid or stranded copper wire that carries the electrical current. It is surrounded by a layer of insulation, which is typically made of a polymer material such as polyethylene or PVC. The insulation layer helps to protect the central conductor from damage and prevent electrical leakage.

The next layer of the cable is typically the neutral conductor, which is a layer of copper or aluminum wires that are arranged concentrically around the central conductor. The neutral conductor is connected to the ground and helps to balance the electrical load in the circuit.

In some types of concentric cable, there may be additional layers of conductors, such as a layer of insulation followed by a layer of hot conductors that carry the electrical current.

Features of concentric cable:

The concentric arrangement of the conductors provides several advantages such as improved conductivity, increased strength and flexibility, and better resistance to corrosion and weather conditions.

Concentric cable is a type of electrical cable that consists of multiple layers of conductors, each layer being insulated from the others. Here are some of the features of concentric cable:

1.Construction: Concentric cable typically has a central conductor, which is surrounded by one or more layers of concentric conductors, each layer being separated by an insulating layer.

2.Shielding: The inner conductor of concentric cable is typically shielded by a layer of metal, such as copper or aluminum, to reduce electromagnetic interference (EMI) and radio frequency interference (RFI).

3.Insulation: Each layer of concentric cable is insulated from the others to prevent short circuits and other electrical issues.

4.Voltage rating: Concentric cable is typically designed for use in low to medium voltage applications, ranging from a few hundred volts to several thousand volts.

5.Flexibility: The flexibility of concentric cable makes it easy to install in a variety of applications, including those where space is limited.

6.Durability: It is designed to withstand harsh environmental conditions, such as extreme temperatures, moisture, and abrasion.

7.Cost: Concentric cable is typically less expensive than other types of electrical cable, making it a cost-effective choice for many applications.

8.Conductivity: Have high electrical conductivity, which makes it efficient for power transmission and data transfer.

9.Corrosion resistance: Some types of concentric cable are designed to resist corrosion, which is important for applications that are exposed to moisture or harsh chemicals.

10.Compatibility: It is compatible with a wide range of electrical equipment and systems, making it a versatile choice for many applications.

11.Safety: Conforms to various safety standards, such as UL and CSA, to ensure that it is safe for use in different environments.

12.Ease of termination: It is easy to terminate with a variety of connectors and termination methods, making it simple to connect to other electrical components and systems.

13.Maintenance: Concentric cable is relatively easy to maintain, requiring only periodic inspections and cleaning to ensure optimal performance and reliability.

Here are the steps to lay concentric cables:

Laying concentric cables involves arranging multiple cables in concentric circles around a central point. This type of cabling is commonly used for power distribution and transmission, as well as for communication and networking.

1.Plan the layout: Determine the length of the run, the number of cables needed, and the spacing between the cables. This will help you determine the diameter of the circle required for the concentric layout.

2.Prepare the cable ends: Strip the insulation from the ends of the cables and crimp on any necessary connectors or terminations.

3.Mark the central point: Use a stake or other marker to identify the center point of the layout.

4.Lay the first cable: Starting at the center point, lay the first cable in a circle around the central point.

5.Lay subsequent cables: Starting at the center point, lay each subsequent cable in a concentric circle around the previous cable.

6.Maintain spacing: As you lay each cable, ensure that it is spaced evenly from the previous cable and that there is no overlap or tangling.

7.Secure the cables: Once all the cables are laid, secure them in place with cable ties or other appropriate fasteners.

8.Test the installation: Test the continuity and performance of the cables to ensure that the installation is successful.

Remember to follow appropriate safety procedures when handling and installing electrical cables, and consult any applicable codes or regulations.

Post categories

Most Popular Posts

-

The 136th Canton Fair welcomes you to participate!

October 12, 2024 -

High temperature cable introduction

July 26, 2024 -

Kenya Power and Energy Exhibition 2024

June 11, 2024 -

Introduction of rubber sheathed cable

June 5, 2024