- Offices Time:24 Hours Online

- Email:[email protected]

- WhatsApp:+8618339938759

Posted on February 24, 2023

What Is An Armored Cable?

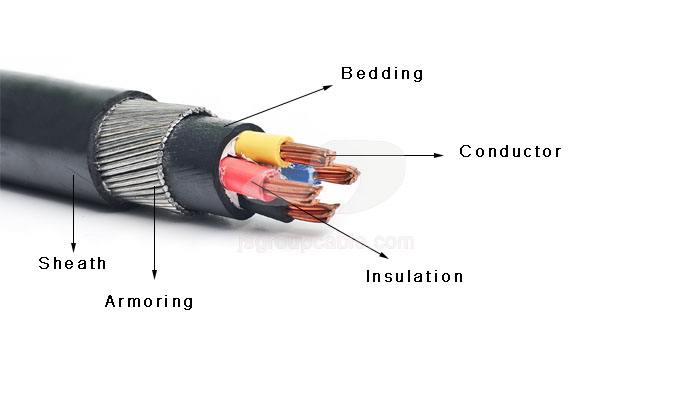

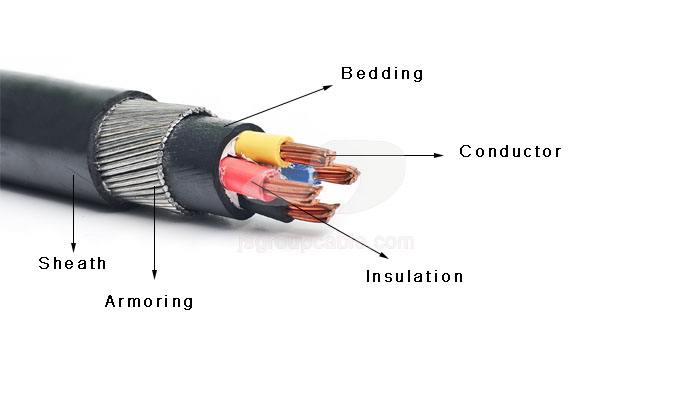

An armored cable, also known as an armored electrical cable or armored cable assembly, is a type of electrical cable that is covered in a protective layer of metal or polymer. This protective layer is typically made of steel or aluminum and is designed to provide additional protection for the electrical wires inside the cable.

Armored cable are commonly used in industrial and commercial applications where the cable may be exposed to physical damage or other hazards. The protective layer helps to prevent damage from abrasion, moisture, chemicals, and other environmental factors. Additionally, the armor can provide additional shielding against electromagnetic interference (EMI).

There are several different types of armored cable available, including armored power cable, armored control cable, and armored instrumentation cable. These cable may be used in a variety of applications, such as in manufacturing plants, oil and gas refineries, and data centers.

Why are cable armored?

Cable are armored to provide additional protection against physical damage, moisture, and other environmental hazards. Electrical cable are essential for transmitting power and data, and they are often installed in harsh environments where they can be exposed to mechanical stress, water, chemicals, and other hazards that can damage or degrade their performance.

The armor layer provides a barrier between the cable’s inner components and the environment, protecting it from physical damage and abrasion. It also provides protection against moisture, which can corrode or short-circuit the conductors and insulation layers.

Armored cable are commonly used in industrial, commercial, and outdoor applications where they are exposed to harsh environments and extreme weather conditions. They are also used in critical applications where the failure of a cable could have serious consequences, such as power distribution systems, control systems, and data centers.

The armor layer enhances the durability and reliability of the cable, reducing the risk of downtime, equipment failure, and safety hazards.

What are the types of armored cable?

Armored cable can provide extra durability and protection from physical damage, moisture, and other environmental hazards. Here are some common types of armored cable:

1.Steel Wire Armored (SWA) Cable

SWA cable have a layer of steel wire around the conductor and insulation layers to provide mechanical protection. They are commonly used in indoor and outdoor installations, including power distribution systems and underground applications.

2.Aluminum Wire Armored (AWA) Cable

AWA cable are similar to SWA cable but use aluminum wire instead of steel wire for the armor layer. They are typically used in low-voltage applications.

3.Lead Sheathed Cable

These cable have a lead outer layer that provides protection against moisture and other environmental factors. They are commonly used in industrial applications and power distribution systems.

4.Braided Cable

Braided cable have a woven layer of metal or polymer fibers that provides protection against mechanical stress and electromagnetic interference. They are commonly used in high-frequency applications and aerospace applications.

5.Metal Clad Cable (MC Cable)

MC cable have a metal sheath that provides protection against physical damage, moisture, and fire. They are commonly used in commercial and residential installations, including wiring for HVAC systems, lighting fixtures, and appliances.

6.Liquid-tight Flexible Metal Conduit (LFMC)

LFMC is a flexible metal conduit with a waterproof, liquid-tight outer layer that provides protection against moisture, oils, and other environmental factors. It is commonly used in industrial applications and outdoor installations.

These are some of the most common types of armored cable, but there are many other variations and specialized types available depending on specific applications and requirements.

Advantages of Armored Cable

Armored cable are electrical cable that are wrapped in a layer of protective armor. Here are some advantages of using armored cable:

1.Protection

Armored cable are designed to provide extra protection to the inner conductor and insulation from damage caused by mechanical impact, crushing, abrasion, or rodent attacks. This makes them ideal for use in harsh environments such as construction sites, industrial facilities, and underground installations.

2.Durability

Armored cable are made of tough materials such as steel or aluminum, which are resistant to corrosion, moisture, and extreme temperatures. They are therefore able to withstand the rigors of harsh environments and last longer than non-armored cable.

3.Safety

Armored cable are designed to meet stringent safety standards and regulations. They are resistant to fire and do not emit toxic fumes when exposed to high temperatures. This makes them ideal for use in buildings and other structures where fire safety is a concern.

4.Flexibility

Armored cable are available in various sizes and lengths, and can be customized to meet specific requirements. They are also easy to install, maintain, and repair, which makes them a popular choice for electrical contractors and engineers.

5.Cost-effective

Although armored cable are generally more expensive than non-armored cable, they are a cost-effective solution in the long run due to their durability and long lifespan. They are also less likely to require repairs or replacement, which saves time and money in the long term.

6.Longevity

Armored cable are built to last, with a lifespan of up to 25 years or more. This means that they require less maintenance and replacement over time, making them a cost-effective solution for long-term use.

7.Electrical Performance

Armored cable are designed to provide excellent electrical performance, with low resistance and minimal voltage drop. This makes them ideal for applications where high levels of electrical performance are required, such as in industrial machinery and equipment.

Armored cable offer a reliable and robust solution for electrical installations in harsh environments, ensuring safety, durability, and protection for the cable and the people using them.

Post categories

Most Popular Posts

-

The 136th Canton Fair welcomes you to participate!

October 12, 2024 -

High temperature cable introduction

July 26, 2024 -

Kenya Power and Energy Exhibition 2024

June 11, 2024 -

Introduction of rubber sheathed cable

June 5, 2024