- Offices Time:24 Hours Online

- Email:[email protected]

- WhatsApp:+8618339938759

Posted on November 9, 2022

Types and advantages of control cables

Control cables are mainly used to transmit control and measurement signals. The control cable is suitable for industrial and mining enterprises and modern high-rise buildings with a rated voltage of 450/750V, 600/1000V and below. As a connection line between various electrical instruments and automated instrumentation devices, it plays a role in transmitting various electrical signals and ensuring the safe and reliable operation of the system.

Control cables can be divided into ordinary control cables, flame-retardant (ZR) control cables, fire-resistant (NH), low-smoke and low-halogen (DLD), low-smoke and halogen-free (DW), high flame-retardant (GZR), Temperature and cold-resistant control cables, etc.

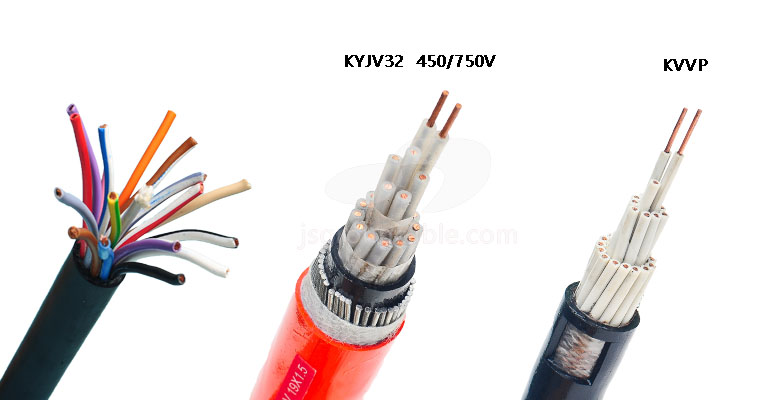

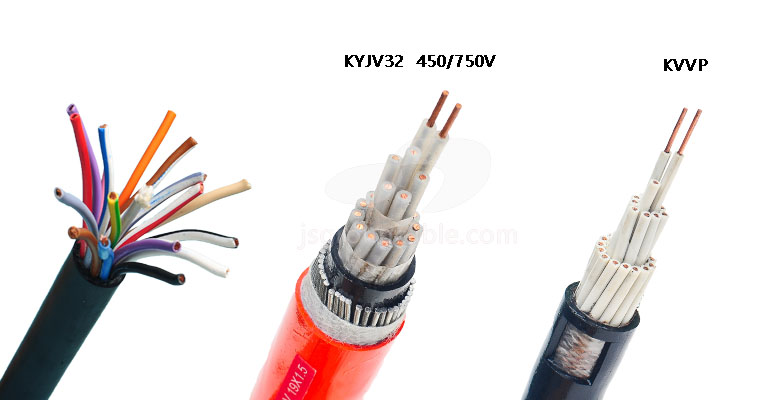

Control cables are generally divided into two series: shielded control cables and unshielded control cables. Both can produce flame-retardant, fire-resistant, low-smoke halogen-free, armored and other types. It is widely used in industrial and mining enterprises, energy and transportation departments, and for control and protection circuits with AC rated voltage below 450/750 volts.

1.Control cable model

(1) The serial code of the first part on the control cable: K–control cable, the code of the second part is the material of the control cable, and there are many kinds of materials of the control cable. The third part of the code is the structural characteristics of the control cable. The fourth part represents the rated voltage, and the rated voltage of the control cable is generally unchanged. The fifth part represents the specification of the control cable, that is, the number of cores and the area of the control cable.

(2) Control cable material code. The material codes of control cables are: V–polyvinyl chloride insulation, YJ–cross-linked polyethylene or cross-linked polyolefin insulation, V–polyvinyl chloride sheath, Y–polyethylene or polyolefin sheath.

(3) Structural feature code. The structural feature codes of the control cable are: P–braided shielding, P2–copper tape shielding, P3–aluminum/plastic composite film shielding, R–soft structure, 2–double steel tape armoring, 3–steel wire Armoured, 2–PVC outer sheath, 3–PE or polyolefin outer sheath.

(4) Control cable specifications. The specification of the control cable represents the number of cores of the control cable * the cross-sectional area of each core, such as copper core XLPE insulated PVC sheathed double steel tape armored control cable, rated voltage 450/750V, 4 cores, 2.5 Square mm: KYJ22-450/750V 4*2.5.

2.Advantages of control cables

(1) It can meet the needs of many electrical appliances. Relatively speaking, during the production process of industrial control cables, the relevant standards of various information in the process of dissemination are fully considered. In this way, it can be ensured that the industrial control cable can meet the performance of many electrical appliances in daily work. And this is a very important point among the characteristics of industrial control cables, which should be kept in mind for consumers.

(2) It has the function of anti-interference. In the process of information dissemination, noise interference and loss are important factors that cause information distortion. Therefore, special processing technology is used in the production process of industrial control cables. In this way, the anti-interference ability of itself can be relatively stronger, especially for important information, it can play a very good protective role.

(3) When understanding the characteristics of industrial control cables, there is another very important factor, that is, the corresponding length is easier to observe. In the daily use process, in the process of using the relevant industrial control cables, the specific location is visually observed, so that you can clarify your own needs, ensure the demand for the use of industrial control cables, and reduce the corresponding errors.

(4) When industrial control cables are wired, they basically go underground, so the wear resistance is relatively strong, and they have good corrosion resistance. Extend the service life of industrial control cables and ensure the overall quality of the control cables.

3.Precautions for control cable installation

(1) Under the eaves

Standard LAN cables can be used only if the cable is not exposed to direct sunlight or extreme heat, and conduit is recommended.

(2) Exterior wall

Avoid direct sunlight on the wall and man-made damage. Cables are exposed to high temperatures in metal conduits or trunkings, and many polymeric materials experience reduced service life at these temperatures.

(3) In the pipeline

If in pipes, pay attention to the damage of plastic pipes and the heat conduction of metal pipes.

(4) Suspended application/overhead cable

Consider cable sag and stress. Whether the cable is exposed to direct sunlight.

(5) Directly laying in the underground cable trench

This environment is the least controlled. The installation of the cable trench should be checked regularly for dryness or dampness. If the shield of the control cable needs to be grounded, the corresponding standards must be observed.

(6) Underground pipelines

In order to facilitate future upgrades, cable replacement and isolation from surface pressure and surrounding environment, auxiliary pipelines are isolated, and auxiliary pipelines are a better method.

Post categories

Most Popular Posts

-

The 136th Canton Fair welcomes you to participate!

October 12, 2024 -

High temperature cable introduction

July 26, 2024 -

Kenya Power and Energy Exhibition 2024

June 11, 2024 -

Introduction of rubber sheathed cable

June 5, 2024