- Offices Time:24 Hours Online

- Email:[email protected]

- WhatsApp:+8618339938759

Posted on January 30, 2023

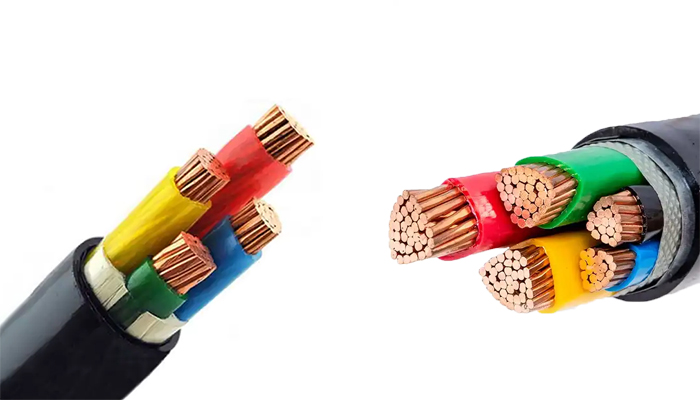

The difference between XLPE insulated cables and ordinary cables

XLPE insulated cables are famous for their good electrical and heat resistance properties, large transmission capacity, light structure, easy bending, simple connection joints, convenient laying and installation, and are not limited by height drops, especially without oil leakage and fire hazards. Widely welcomed by the public. In recent years, it has developed into high voltage and ultra-high voltage fields, showing a trend of gradually replacing oil-paper cables. Let’s talk about this eco-friendly high-quality cable in detail. Do you know what are the advantages of XLPE insulated cables compared to ordinary insulated cables?

Let’s talk to you about the difference between XLPE insulated cables and ordinary insulated cables:

1.Temperature resistance: The temperature resistance level of ordinary insulated cables is generally about 70°C, and the temperature resistance of XLPE insulated cables can reach about 90°C.

2.Different ampacity: For cables with the same conductor cross-sectional area, the ampacity of XLPE insulated cables should be greater than that of ordinary insulated cables.

3.Scope of application: When ordinary insulated cables are burned, toxic HCl fumes will be released, and ordinary insulated cables cannot be used when fire protection requires low toxicity. XLPE insulated cables are suitable for distribution networks, industrial devices and other fields that require large-capacity electricity. They are used for fixed laying on power transmission and distribution lines with AC 50Hz and rated voltage 6kV-35kV. The main function is to transmit electric energy.

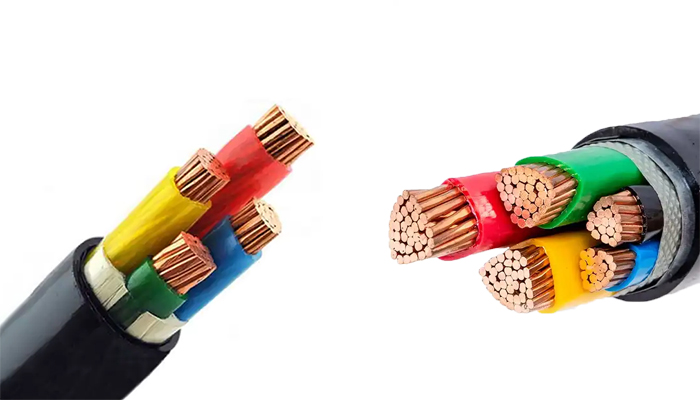

Advantages of XLPE insulated cables:

1.XLPE insulated cable is a kind of cable suitable for distribution network and other fields, which has the incomparable advantages of PVC insulated cable. It has the characteristics of simple structure, light weight, good heat resistance, strong load capacity, not easy to melt, chemical corrosion resistance and high mechanical strength.

2.Cross-linked polyethylene is mainly a cross-linked polyethylene that converts a linear molecular structure into a three-dimensional network structure by chemical or physical means. To a large extent, it improves the thermomechanical properties of polyethylene and maintains excellent electrical properties. performance.

3.The rated operating temperature of the XLPE insulated cable conductor can reach 90°C, which is higher than the rated operating temperature of PVC insulated cables and PE insulated cables, thereby further improving the carrying capacity of the cable.

4.It has excellent thermal mechanical properties, excellent electrical properties and chemical corrosion resistance, and has the advantages of simple structure, light weight, and unlimited laying. It is a new type of cable widely used in urban power grids, mines and factories.

5.Cross-linked polyethylene maintains the original excellent insulation properties of polyethylene, and the insulation resistance is further expanded. Its dielectric loss tangent is not large, and it is not greatly affected by temperature.

6.Because of the creation of new ionic bonds between biological macromolecules, the strength, bending stiffness, wear resistance and impact resistance of cross-linked polyethylene are all improved, thereby filling the gap where polyethylene is susceptible to natural environmental stress and cracking defect.

7.Cross-linked polyethylene has strong corrosion resistance and wear resistance, and its ignition substances are mainly water and carbon dioxide, which is less harmful to the natural environment and meets the contemporary safety fire protection regulations.

Advantages of XLPE Insulation

Initially, polyvinyl chloride was the main insulating material for wires and cables. However, because PVC contains halogens, when wires and cables burn in an accident, they release toxic fumes, which seriously pollute the environment and hinder firefighters from fighting fires and evacuating people. Cross-linked polyethylene is an environmentally friendly wire and cable. It does not produce harmful substances when burned, does not contain halogens, and does not emit toxic gases during daily operation.

The heat resistance of XLPE insulated cables is higher than that of polyvinyl chloride, and can be used for a long time below 90°C, and the heat resistance can reach 250°C when short-circuited; the insulation resistance is high, the dielectric loss tangent is small, and basically does not change with temperature; good abrasion resistance and environmental stress cracking resistance. XLPE cables produce carbon dioxide and water when they burn, while hydrogen chloride is a harmful gas produced when PVC cables burn. In addition, the density of cross-linked polyethylene is about 40% lower than that of polyvinyl chloride, which will reduce the quality of overhead lines.

Post categories

Most Popular Posts

-

The 136th Canton Fair welcomes you to participate!

October 12, 2024 -

High temperature cable introduction

July 26, 2024 -

Kenya Power and Energy Exhibition 2024

June 11, 2024 -

Introduction of rubber sheathed cable

June 5, 2024