- Offices Time:24 Hours Online

- Email:[email protected]

- WhatsApp:+8618339938759

Posted on January 10, 2023

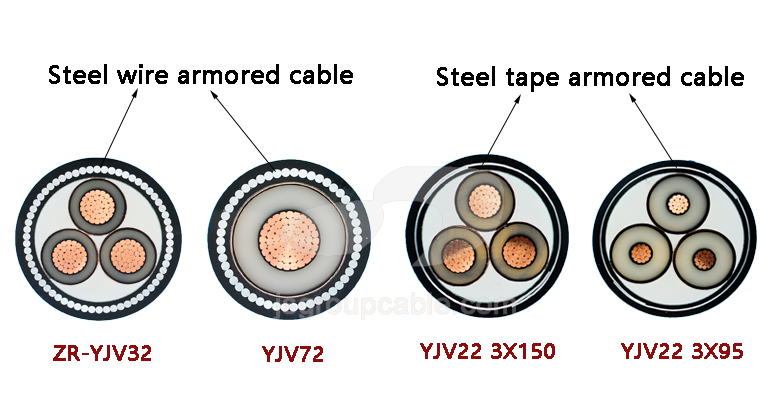

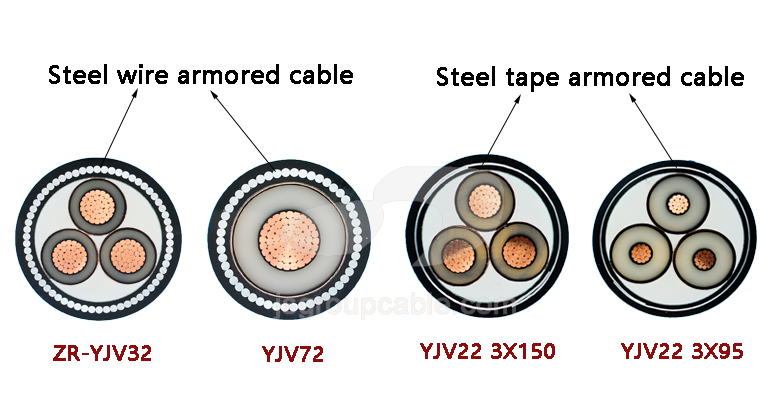

The difference between steel wire armored cable and steel tape armored cable

Armored cables are made from various cable materials in an insulated metal sheath that is processed into a flexible and strong assembly. Armored cables include armored thermocouples, armored thermal resistors, armored heaters and armored wires, which are mainly used for temperature measurement, signal transmission and special heating in chemical industry, metallurgy, machinery manufacturing, power generation and scientific experiments. Installing thermocouples consumes the most. Armored cables can be attached to any type of cable to enhance the mechanical protection of the cable, increase the mechanical strength of the cable, and improve corrosion resistance. This is a cable designed for areas subject to mechanical damage and erosion. The laying method is not limited, and it is generally suitable for direct burial laying in rocky areas.

The difference between steel wire armored and steel tape armored cables

Armored cables are further divided into steel tape armored cables and steel wire armored cables. The main differences are:

1.Application. Steel tape armoring is only used for laying directly buried cables or ordinary pipelines, ordinary ground, tunnels, etc. Thin steel wire armor not only inherits the advantages of steel tape armor, but also can withstand general longitudinal tension, so it is widely used in short-distance overhead laying or vertical laying. There are many steel wire armored cables abroad!

2.Cable price: steel wire armor is relatively expensive. Since the production process of steel wire armor is relatively complicated, the cost is relatively high.

3.Current-carrying capacity.The distance is not large, and reverse magnetic steel strips or steel wires are required. Depending on the application environment, cables of different armoring methods are used. Steel tape armoring can bear the mechanical pressure, and steel wire armoring can bear the tensile force of the mechanical equipment.

4.Different armoring materials.one is flat steel strip and the other is round steel wire. Steel tape armoring is mainly to increase the compressive strength of the cable. It is used in a large amount when the cable is directly buried.

In short, according to different use environments, cables with different armor forms are selected. Steel tape armor can withstand mechanical pressure, and steel wire armor can withstand mechanical tension.

Classification of armored cables:

Armoring is divided into steel tape armoring (22, 23), thin steel wire armoring (32, 33) and thick steel wire armoring (42, 43).

The models of steel tape armored cables are VV22, VVP22, ZRVV22 and NH-VV2.

Steel tape armored cables for control cables, including KVV22, KVP2, KVP22 and ZR-KVV22 steel wire armored power cables.

There are VV32, YJV32, ZR-VV32 steel wire armored control cables, KVV32 KVVP32 armored communication cables, HYA53, HYAT53, HYA23, HYA22, HYA22 (rodent-proof, buried).

Use of armored cables:

Armored cables can be attached to any type of cable to increase the mechanical resistance, corrosion resistance and impact resistance of the cable. This is a wire and cable designed for use in areas subject to mechanical damage and corrosion. Laying methods are not restricted and are generally more suitable for direct burial in rocky areas.

Armored cables are usually fixed power cables. Generally speaking, they are fixed in one place and basically do not move. Power lines transmit electrical energy.

In addition to this, the purpose of adding an armor layer to the cable can also enhance mechanical protection, such as tensile strength and compressive strength, and extend the service life.

The armor has a certain ability to resist external forces, and it can also prevent rats from biting, so as not to cause energy transmission problems through the armor. The armor has a large bend radius and the armor can be grounded to protect the cable.

Post categories

Most Popular Posts

-

The 136th Canton Fair welcomes you to participate!

October 12, 2024 -

High temperature cable introduction

July 26, 2024 -

Kenya Power and Energy Exhibition 2024

June 11, 2024 -

Introduction of rubber sheathed cable

June 5, 2024