- Offices Time:24 Hours Online

- Email:[email protected]

- WhatsApp:+8618339938759

Posted on December 23, 2022

The difference between medium voltage cables and high voltage cables

Many people know low-voltage cables and high-voltage cables, but few people know medium-voltage cables. The voltage range of medium-voltage cables is between 6KV and 33KV. The actual production and application fields include petrochemical, transportation, wastewater treatment, and food processing. Etc. is also an important application cable type.

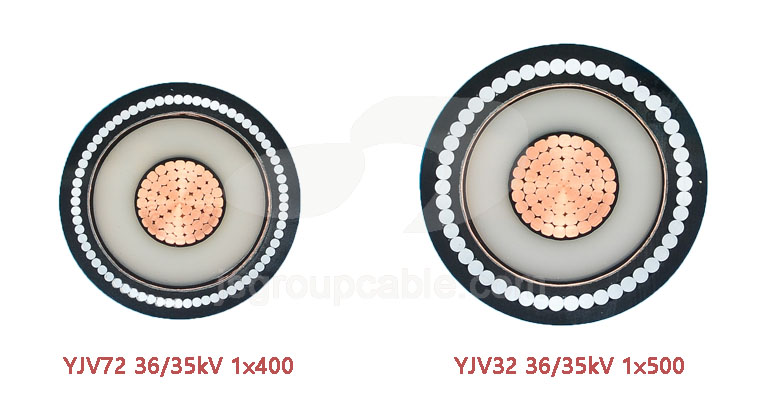

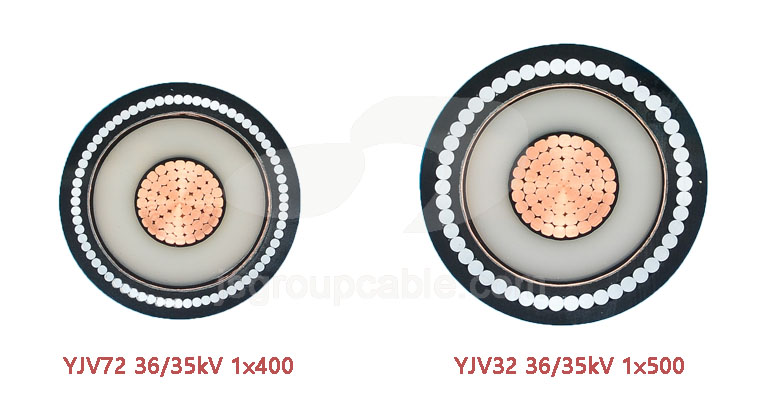

With the economic development in recent years, the importance of medium-voltage cables has gradually become prominent, and the demand for medium-voltage cables in all walks of life is also increasing. Because of their characteristic requirements, medium-voltage cables have different sizes and types. For special requirements, the structure of medium-voltage cables is much more complicated than that of low-voltage cables. Moreover, the materials used and the production process are different. The insulation layer of medium voltage cables generally consists of three layers, conductor shielding layer, insulating material, and insulating shielding layer.

Also the raw material for medium voltage cables is different, even if the insulation has the same designation as for low voltage cables, the raw material itself is different to ensure a purer insulation. Color masterbatches for low-voltage cables are not permitted for core identification.

In the use of medium-voltage cables, special attention should be paid to common faults. Most of the reasons are caused by the aging of cable infrastructure. Generally, partial discharge is actually a precursor to failure, because it provides evidence that the cable has begun to deteriorate. , which will cause malfunctions and malfunctions, and subsequent power outages.

Cable aging typically begins by affecting cable insulation by reducing electrical resistance, which is a key indicator of defects including moisture or air pockets, water trees, electrical trees, and other problems. In addition, split sheaths can be affected by aging, increasing the risk of reaction or corrosion, which can cause problems later in service.

Therefore, when selecting cables, you must purchase qualified and high-quality products, because low-quality cables often have premature aging problems, and aging is the root cause of many failures.

Where can medium voltage cables be used?

In our power grid, the medium-voltage grid can provide electricity for an area, but it cannot be used for inter-regional power exchange, they are the voltage levels between the high-voltage grid and building installations. Some larger power customers, such as industrial companies, hospitals, large swimming pools and large broadcast TV towers, usually have dedicated medium voltage power supplies provided by internal substations. This voltage is also referred to as medium voltage for railway power supplies with traction supply voltages between 15kV and 25kV.

As energy demands increase, large systems such as cranes or conveyor systems also require power from medium voltage cables. In the case of using the same cable, a lower current can be transmitted by increasing the voltage, which can reduce the nominal cross-sectional area of the cable conductor. However, unlike fixed-installation wiring systems, in these applications moving parts must be powered. To this end, the cables must be capable of long-travel applications with increasingly high dynamics. Therefore, medium voltage cables in these applications must be specially designed for long-term movement.

Construction and materials of medium voltage cables

Medium voltage cable designs can come in different sizes and types. The structure is much more complicated than that of low-voltage cables.

The difference between medium voltage cables and low voltage cables is not only how the cables are constructed, but also from the manufacturing process and raw materials.

In medium voltage cables, the insulation process is quite different from that of low voltage cables.

1.The medium voltage cable consists of three layers instead of one layer: conductor shielding layer, insulating material, and insulating shielding layer.

2.The insulation process for medium voltages is achieved by using CCV lines instead of conventional horizontal extruders, as is the case for low voltage cables.

3.Metal screens are commonly used in the construction of medium voltage cables for low voltage cables dedicated to specific applications.

The difference between medium voltage cables and high voltage cables

1.The main difference between medium voltage cables and high voltage cables is their insulation and insulation materials. Medium voltage cables use copper or high purity electrolytic aluminum. Their insulating layer is cross-linked, which helps to improve the electric field distribution on the surface of the conductor. Both high and medium voltage cables use metallic shields to shield the connectors of the conductors from electric fields.

2.The main difference between medium voltage cables and high voltage cables is that high voltage cables are insulated and higher conductors are used. Copper is a better conductor than aluminum, which is used in high voltage cables. High voltage cables usually have an insulating sheath whereas overhead wiring does not. This openness is good for heat dissipation and maximum current flow, but it also has disadvantages. Higher voltage wires also require greater wire spacing to prevent arcing and short circuits.

3.The difference between medium voltage cables and high voltage cables depends on the type of electricity you use. The two are often used for different applications. Medium voltage cables are used in local grids and do not carry national electricity. They maintain the voltage between the high voltage network and the premises installation. Medium voltage cables are generally used for larger electricity consumers. They are used in traction power networks.

Post categories

Most Popular Posts

-

The 136th Canton Fair welcomes you to participate!

October 12, 2024 -

High temperature cable introduction

July 26, 2024 -

Kenya Power and Energy Exhibition 2024

June 11, 2024 -

Introduction of rubber sheathed cable

June 5, 2024