- Offices Time:24 Hours Online

- Email:[email protected]

- WhatsApp:+8618339938759

STA Cable

STA Cable

STA cable is a type of power cable that has an additional layer of steel tape armor for mechanical protection. The armor layer is typically made of galvanized steel, which provides excellent resistance against physical damage, moisture, and rodents.

- Description

1.Application Of STA Cable

Underground power distribution:

STA cable are commonly used for underground power distribution systems due to their high mechanical protection against physical damage and moisture. The steel tape armor layer also provides protection against rodents and other pests.

Overhead power distribution:

Used in overhead power distribution systems, especially in areas where the cables are exposed to extreme weather conditions.

Mining:

Used in the mining industry, where the cables are subjected to harsh environments and mechanical stress.

Oil and gas industries:

Used in the oil and gas industries for power distribution and control applications, where they are exposed to harsh environments such as extreme temperatures, moisture, and corrosive chemicals.

Marine and offshore applications:

STA cables are also used in marine and offshore applications, where they are exposed to saltwater, high humidity, and mechanical stress.

Construction:

Used in various construction applications, such as in the installation of elevators, escalators, and other heavy machinery.

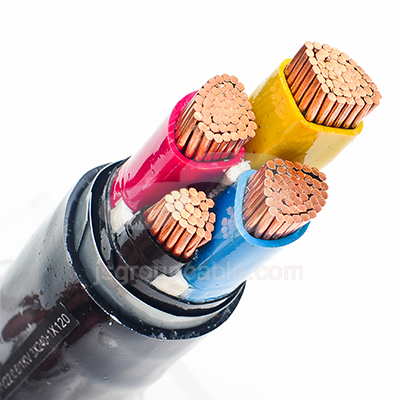

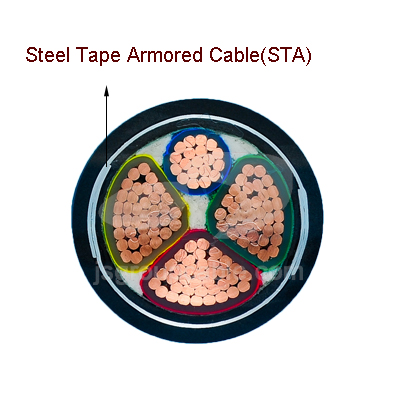

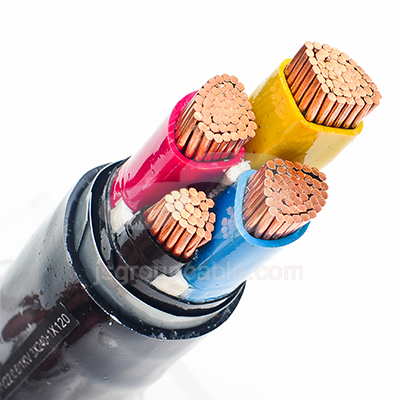

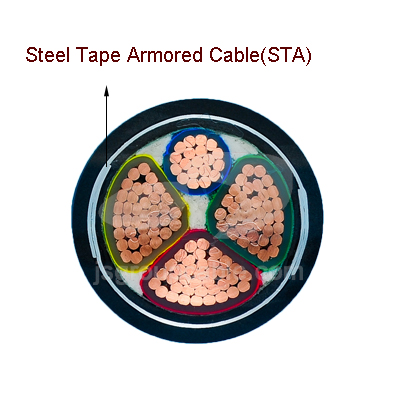

2.Construction Of STA Cable

Conductor:

The cable begins with one or more conductors, which are typically made of copper or aluminum. The conductors carry the electrical current and serve as the core of the cable.

Insulation:

The conductors are usually insulated with a layer of thermoplastic or thermosetting material, such as PVC (polyvinyl chloride), XLPE (cross-linked polyethylene), or EPR (ethylene propylene rubber). The insulation provides electrical insulation to prevent current leakage and short-circuits.

Inner Sheath:

Over the insulated conductors, a layer of inner sheath is applied. The inner sheath is typically made of PVC or PE (polyethylene) and provides additional protection to the conductors from moisture, chemicals, and mechanical stress.

Steel Tape Armor:

The steel tape armor is then applied over the inner sheath. The steel tape is typically made of galvanized steel or stainless steel, and it is helically wrapped around the cable core with an overlap to provide mechanical protection. The steel tape armor protects the cable from external forces, such as crushing, bending, and impact, making the cable suitable for installation in harsh environments.

Outer Sheath:

The cable is then covered with an outer sheath, also known as the jacket. The outer sheath is typically made of PVC, PE, or LSZH (low smoke zero halogen) material, depending on the application requirements. The outer sheath provides additional protection against moisture, chemicals, UV radiation, and other environmental factors.

Product Category

Latests News

-

The 136th Canton Fair welcomes you to participate!

October 12, 2024 -

High temperature cable introduction

July 26, 2024 -

Kenya Power and Energy Exhibition 2024

June 11, 2024 -

Introduction of rubber sheathed cable

June 5, 2024