- Offices Time:24 Hours Online

- Email:[email protected]

- WhatsApp:+8618339938759

Posted on February 10, 2023

Scope and selection of 10kV power cable

10kV power cable is a kind of power cable, which refers to the power cable used to transmit 10KV-35KV, and is mostly used in the main road of power transmission. In project engineering, many copper core power cables are used as the main road of the power supply system, while the application of aluminum core power cables is less, especially in the higher voltage power system, the more copper core cables are selected. So what are the types of 10kV power cable? What is the specific scope of use? And how to choose the conductor?

10kV power cable type:

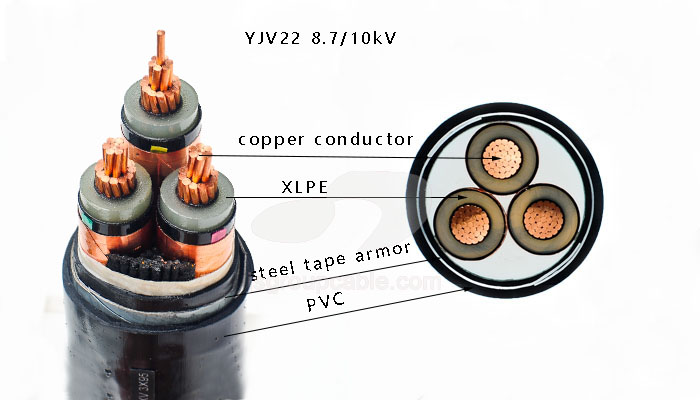

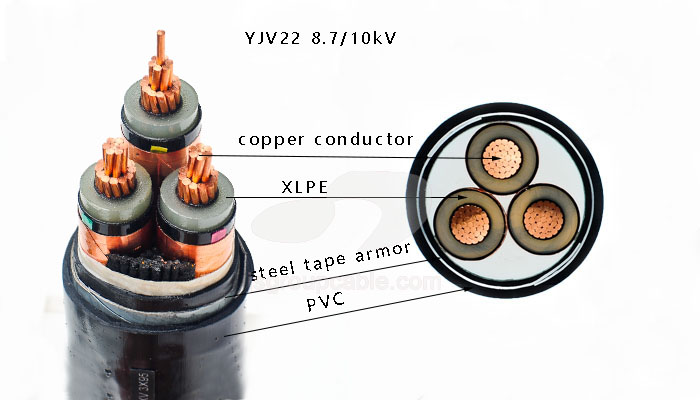

YJV cable: XLPE insulated PVC sheathed power cable

VV cable: Copper core conductor PVC insulated and PVC sheathed power cable

YJLV cable: Aluminum core PVC insulated power cable

VLV cable: Aluminum core PVC insulated PVC sheathed power cable

10kV power cable scope of application:

1.According to the municipal planning, it is clearly required to use cable lines and have corresponding conditions.

2.The corridor is narrow, and the overhead line is difficult to pass and cannot meet the power supply demand.

3.Coastal areas vulnerable to tropical storms.

4.Economic development zones with high requirements on power supply reliability and conditions.

5.Pass through the section of key scenic tourist areas.

6.Special requirements for power grid structure or operation safety.

10kV power cable path selection:

1.The cable line should be combined with the overall planning of the town, should be arranged uniformly with various pipelines and other municipal facilities, and should be approved by the planning department.

2.The cable laying path should comprehensively consider factors such as path length, construction, operation and maintenance convenience, and make overall plans to achieve economical rationality, safety and applicability.

3.The place where excavation and construction may be possible should be avoided to avoid the cables from being subjected to mechanical external force, overheating, corrosion and other hazards.

4.It should be convenient for laying and maintenance, and should be conducive to the layout and construction of cable joints and terminals.

5.The cable should meet the requirements of the allowable bending radius of the cable in any laying method and all path conditions where the up, down, left, and right changes.

6.In case of collapsible loess, silt, permafrost and other special geology, corresponding foundation treatment should be carried out.

10kV power cable selection principle:

1.The selection of power cables should meet load requirements, thermal stability verification, laying conditions, installation conditions, requirements for cable bodies, transportation conditions, etc.

2.The power cable adopts XLPE insulated cable.

3.The selection of the cable interface should be based on the rated current carrying capacity of the cable under different laying conditions, after considering factors such as ambient temperature, parallel laying, thermal resistance coefficient, and burial depth.

4.For high-altitude areas with an altitude of more than 1000 meters and less than 4000 meters, due to the low temperature, some materials in the electrical equipment will become hard and brittle, and the normal operation of the imaging equipment will be prevented.

5.Due to the large temperature difference between day and night, it is easy to generate condensation and deform parts. cracking etc. Therefore, the selection of cable equipment in the plateau area should be combined with the operation experience of the area to put forward corresponding special requirements. It is necessary to check its electrical parameters or select plateau type electrical equipment. The minimum long-term service temperature of XLPE insulated power cables is -40°C .

10kV power cable conductor material selection:

Cable conductors are usually made of copper or aluminum, but copper conductors should be used in the following situations:

1.Important power sources, mobile electrical equipment, etc. need to be connected to circuits with high reliability.

2.Harsh working environment such as severe vibration, explosion hazard or corrosion to aluminum.

3.Fire-resistant cables.

4.Arranged close to high temperature equipment.

5.Public facilities with high safety requirements.

6.When the working current is large, the number of cables needs to be increased.

Post categories

Most Popular Posts

-

The 136th Canton Fair welcomes you to participate!

October 12, 2024 -

High temperature cable introduction

July 26, 2024 -

Kenya Power and Energy Exhibition 2024

June 11, 2024 -

Introduction of rubber sheathed cable

June 5, 2024