- Offices Time:24 Hours Online

- Email:[email protected]

- WhatsApp:+8618339938759

Posted on February 9, 2023

Precautions for using Aerial Bundled Cable

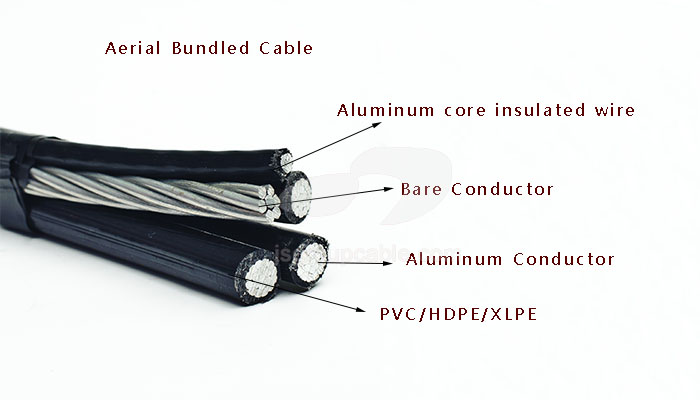

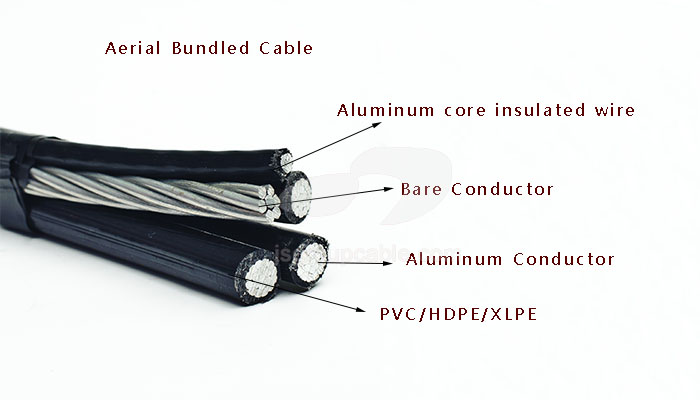

Aerial Bundled Cable is a cable that bundles multiple wires together. The wires can be insulated wires or bare wires. Compared with other wires, it not only takes up less space, saves channels, but also is simple in construction and convenient in operation and maintenance. In addition, Aerial Bundled Cable can also reduce losses, improve voltage quality, and ensure safer and more reliable power supply. Therefore, in recent years, it is often used in the construction and transformation of low-voltage power grids in cities and rural areas.

Aerial Bundled Cable Notes:

Due to the short application time of Aerial Bundled Cable, some users do not know much about its performance and installation environment, so we have summarized some experiences.

1.It should be constructed under the condition of 0~40℃ and dry weather. Because the Aerial Bundled Cable is below 0°C, the temperature is low, and the hardness of the wire increases accordingly. If the construction certificate is folded back and forth, the insulation material on the surface of the wire will be damaged and cracks will occur. When it encounters rain erosion, it will accelerate. Insulation aging, forming a hidden danger.

2.Since the Aerial Bundled Cable is a compact wire, if you do not pay attention during the construction process, the insulation layer will be damaged, and the damage of the insulation layer will easily cause a short circuit between the distances. This kind of problem is more likely to occur. Therefore, special attention should be paid during construction. The defense line must not be directly dragged on the ground, towers, insulators or other objects to prevent damage to the insulation layer.

3.The Aerial Bundled Cable should be firmly connected at the connection point and ensure good contact. On the one hand, it can ensure the safety of the line operation, and on the other hand, it can also reduce resistance and reduce loss. Install an insulating rainproof cover at the connection point and fixed point of the wire, and take waterproof measures to prevent rainwater from corroding the wire.

4.Inflammable and explosive materials should be avoided, and insulating and flame-retardant material pipes should be installed in dangerous areas to prevent fires. In addition, when erecting, there should be a certain safe distance from the trees, and the wires should not be touched, otherwise the friction between the trees and the wires will easily damage the insulation layer.

Aerial Bundled Cable is to wrap the insulating material on the outside of the conductor with different thicknesses according to the requirements of its withstand voltage, which plays a role in isolating the live wire from the outside world. After the wire is energized, it will generate heat. Therefore, an ideal insulating material should have good insulation and thermal conductivity, and should have good advantages in heat resistance, aging resistance, and mechanical properties. The insulation materials used in insulated wires are generally weather-resistant polyvinyl chloride, polyethylene, high-density polyethylene, cross-linked polyethylene, etc., which are black mixtures.

Types of Aerial Bundled Cable Insulation:

1.Polyvinyl chloride insulating material (PVC)

It has good electrical and mechanical properties, relatively stable to acid and alkali organic chemical components, moisture-resistant, flame-retardant, low cost and easy to process. However, compared with other insulating materials, it has low insulation resistance and poor heat resistance. Its long-term allowable working temperature should not exceed 70°C. Therefore, PVC insulation materials are generally only suitable for the outer sheath of low-voltage insulated wires or Aerial Bundled Cable.

2.Polyethylene insulation material (PE)

It has excellent electrical properties, good chemical stability, good solubility resistance at room temperature, very stable performance against non-oxygen acids and alkalis, and good moisture resistance and cold resistance. However, the softening temperature of PVC insulation material is relatively low, and its long-term allowable working temperature should not exceed 70°C.

3.High-density polyethylene insulation material (HDPE)

except that its long-term allowable working temperature should not exceed 70°C and it is not flame-retardant, its other main electrical and mechanical properties are close to those of cross-linked polyethylene materials.

4.Cross-linked polyethylene insulation material (XLPE)

It is formed by converting the linear molecular structure of polyethylene into a network structure by cross-linking. Its electrical properties are close to those of polyethylene, and its heat resistance is good. Its long-term allowable working temperature is 90°C, it has strong overload resistance, and can avoid environmental stress cracking. Its mechanical and physical properties are better than PVC (polyvinyl chloride) and PE insulation materials.

Post categories

Most Popular Posts

-

The 136th Canton Fair welcomes you to participate!

October 12, 2024 -

High temperature cable introduction

July 26, 2024 -

Kenya Power and Energy Exhibition 2024

June 11, 2024 -

Introduction of rubber sheathed cable

June 5, 2024