- Offices Time:24 Hours Online

- Email:[email protected]

- WhatsApp:+8618339938759

LSZH Cable

LSZH Cable

LSZH cable are designed to minimize the emission of smoke and halogen gases, making them suitable for use in enclosed spaces such as buildings, tunnels, aircraft, ships, and other confined areas.

- Description

1.Application Of LSZH Cable

LSZH (Low Smoke Zero Halogen) cable is a type of cable that is designed to emit minimal smoke and no toxic halogen gases when exposed to fire or high temperatures. It is commonly used in environments where safety and low toxicity are a priority, such as in public buildings, data centers, transportation systems, and other areas where people and sensitive equipment may be present. Some common applications include:

Building infrastructure:

LSZH cables are widely used in building infrastructure, including electrical wiring, communications cabling, and security systems. They are often used in areas such as hospitals, schools, airports, and commercial buildings where the release of toxic fumes in the event of a fire could pose a significant health risk to occupants.

Data centers:

Data centers require high-performance cabling solutions that meet stringent safety standards. LSZH cables are commonly used for data communications, such as Ethernet cables, fiber optic cables, and patch cords, within data centers to ensure that any potential fire hazard is minimized and the release of toxic gases is limited in case of a fire.

Transportation systems:

LSZH cables are used in various transportation systems, including railways, airports, and ships, where safety is critical. These cables are used for communication, signaling, power distribution, and other applications to ensure that in case of a fire, the cables do not emit toxic gases that could harm passengers or crew.

Industrial environments:

LSZH cables are used in industrial environments where safety is a top priority. They are commonly used in manufacturing facilities, oil and gas refineries, and chemical plants to minimize the release of toxic gases in case of a fire or high-temperature event.

Military and defense applications:

LSZH cables are also used in military and defense applications where safety and low toxicity are crucial. They are used for communication, power distribution, and other critical systems in military vehicles, aircraft, and ships to ensure that the cables do not pose a health risk to personnel in case of a fire or other emergency situations.

Residential and commercial installations:

LSZH cables are also used in residential and commercial installations, particularly in areas where building codes or regulations require low smoke and low toxicity cabling. These cables are used for various applications such as electrical wiring, communication cabling, and security systems to ensure the safety of occupants in case of a fire.

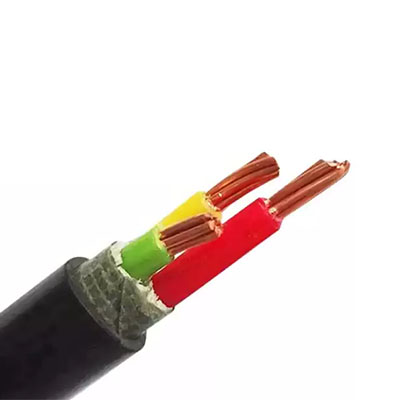

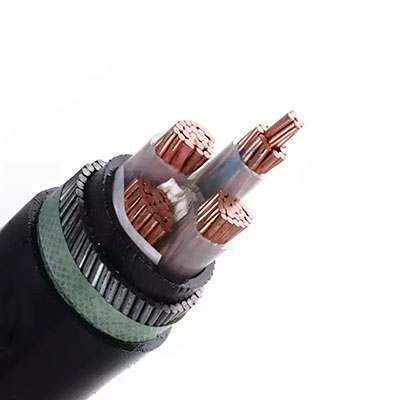

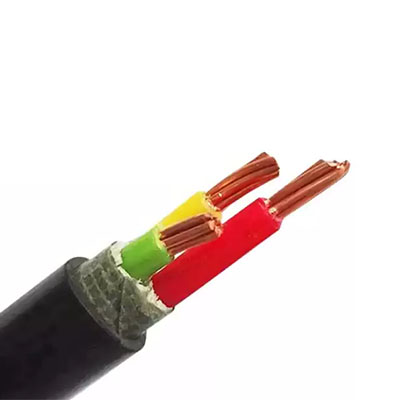

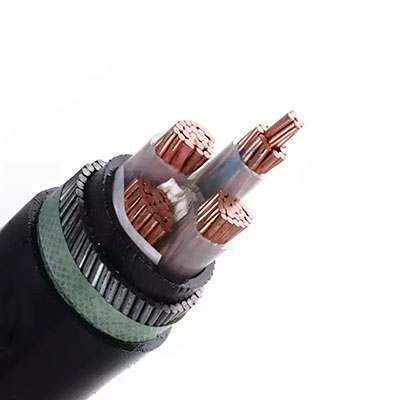

2.Construction Of LSZH Cable

Conductor:

The conductor is the core of the cable and is responsible for carrying the electrical signals or power. It is typically made of copper or aluminum, and it is usually coated with a layer of insulation material that meets LSZH requirements. The insulation material is usually halogen-free and has low smoke and low toxicity properties.

Insulation:

LSZH cables use insulation materials that have low smoke and low toxicity properties. Common insulation materials used in LSZH cables include cross-linked polyethylene (XLPE), polyethylene (PE), or polypropylene (PP), which are halogen-free and produce minimal smoke and toxic gases when exposed to fire.

Jacket:

The jacket is the outer protective covering of the cable. In LSZH cables, the jacket material is also halogen-free and designed to emit minimal smoke and no toxic gases when burned. LSZH jacket materials are typically made of thermoplastic compounds that have low toxicity properties, such as thermoplastic elastomers (TPE) or polyvinyl chloride (PVC) formulations that do not contain halogen additives.

Filler or Barrier Tape:

Some LSZH cables may include a filler or barrier tape, which is used to provide additional protection and performance characteristics. These tapes are usually made of LSZH materials that can help reduce the spread of smoke and toxic gases in the event of a fire.

Shielding (for applicable cables):

LSZH cables that are used for data communications, such as Ethernet cables or fiber optic cables, may also include shielding to protect against electromagnetic interference (EMI) or radio frequency interference (RFI). Shielding is typically made of metal, such as aluminum or copper, and it is coated with LSZH materials to ensure low smoke and low toxicity properties.

Color code:

LSZH cables may also have specific color codes for easy identification and compliance with industry standards. The color code may vary depending on the type of cable and its specific application.

Product Category

Latests News

-

The 136th Canton Fair welcomes you to participate!

October 12, 2024 -

High temperature cable introduction

July 26, 2024 -

Kenya Power and Energy Exhibition 2024

June 11, 2024 -

Introduction of rubber sheathed cable

June 5, 2024