- Offices Time:24 Hours Online

- Email:[email protected]

- WhatsApp:+8618339938759

Posted on June 5, 2024

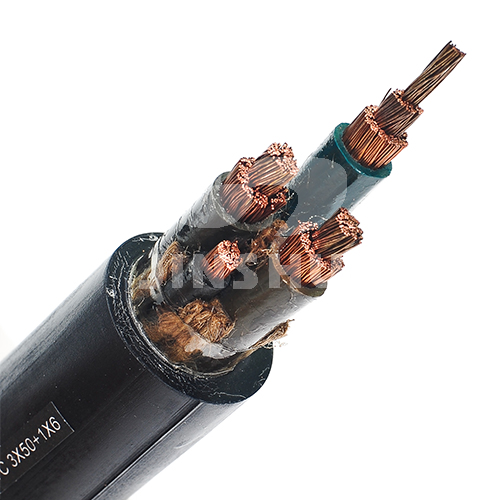

Introduction of rubber sheathed cable

Rubber sheathed cables are widely used in various electrical equipment, such as mobile power cords for daily electrical appliances, electric machinery, electrical devices and appliances, and can be used in indoor or outdoor environments. According to the mechanical external force on the cable, it is divided into three categories in terms of product structure: light, medium and heavy, and there is also appropriate connection in the cross section. Generally, light rubber sheathed cables are used in daily electrical appliances and small electric equipment, requiring softness, lightness and good bending performance; medium rubber sheathed cables are widely used in agricultural electrification in addition to industrial use, and heavy cables are used in occasions such as port machinery, searchlights, and large-scale hydraulic drainage and irrigation stations in the family industry. This type of product has good versatility, complete series specifications, good performance and stability.

Waterproof rubber sheathed cables and cables for submersible pumps are mainly used for submersible motors. The models are JHS and JHSB.

Cables for radio devices currently mainly produce two types of rubber sheathed cables (one shielded and one unshielded), which can basically meet the requirements. The models are WYHD and WYHDP.

Photographic cable products, in line with the development of new light sources, have small structures and good performance, meet the needs of indoor and outdoor work, and gradually replace some heavy and old products with poor heat resistance.

Advantages of rubber sheathed cables

1. Rubber sheathed cables have unparalleled flexibility compared to other common cables

2. Excellent electrical insulation and chemical stability

3. Good physical and mechanical properties and wear resistance

4. By adding special rubber compounding agents, it can meet high requirements such as oil resistance, flame retardancy, cold resistance and heat resistance.

Rubber Sheathed Cables Features

Conductive core

The flexibility requirements are highest for electric drill cables and mining machine cables; the conductor structure adopts the following measures: 1. Use softer thin-diameter copper single wires, bundle and twist with small pitch. The bending and torsion of the entire cable is also affected by the insulation and sheath structure, so it cannot be considered that the thinner the single wire and the smaller the pitch, the better. 2. The use of co-directional bundle twisting and twisting can improve flexibility. 3. In order to facilitate the relative sliding of the wire in the insulation layer and facilitate installation and maintenance. The single wire of the electric drill cable and the small-section mining machine cable should be tinned, and the large-section mining machine cable should be isolated and insulated with paper tape outside the conductor.

Insulation layer

It is required to have sufficient electrical insulation performance: 1. Use rubber with a rubber content of not less than 35%; 2. The insulation thickness is thicker than that of general rubber-sheathed cables. 3. Use rubber with good electrical properties and a good rubber extrusion process (such as a continuous rubber extrusion vulcanization production line).

Shielding layer

When using semi-conductive rubber as the shielding layer, its transition resistance should meet the standard requirements to ensure that the relay protection system can operate reliably under accident conditions.

Post categories

Most Popular Posts

-

The 136th Canton Fair welcomes you to participate!

October 12, 2024 -

High temperature cable introduction

July 26, 2024 -

Kenya Power and Energy Exhibition 2024

June 11, 2024 -

Introduction of rubber sheathed cable

June 5, 2024