- Offices Time:24 Hours Online

- Email:[email protected]

- WhatsApp:+8618339938759

Posted on November 23, 2023

How to choose control cables?

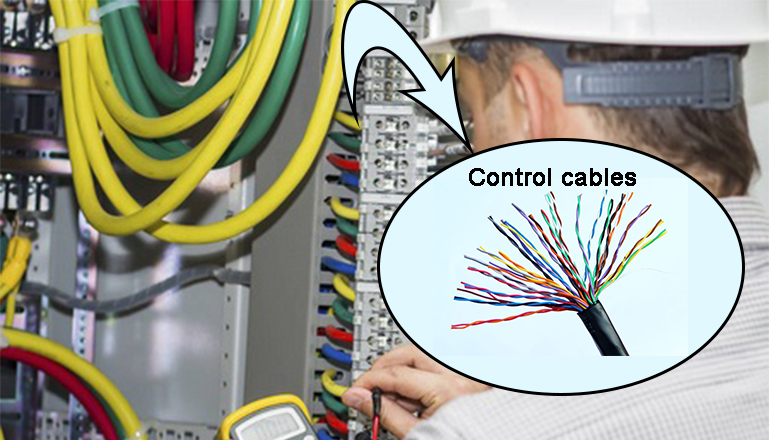

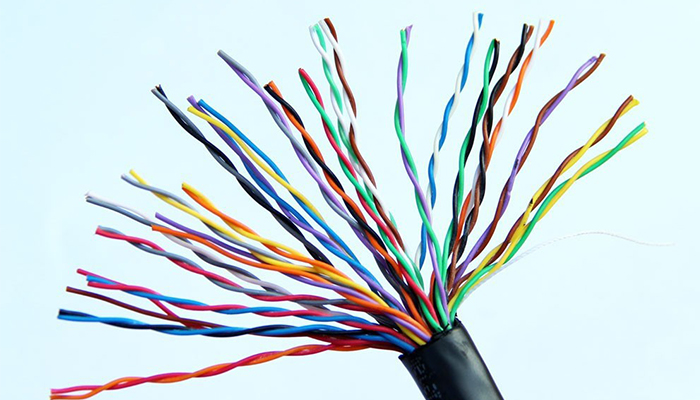

The wire and cable industry has a wide range of products and a wide range of applications, involving many industries such as electric power, construction communications, manufacturing, etc., and is closely related to various sectors of the national economy. In real life, people always confuse power lines and control lines, making it difficult to distinguish between power lines. lines and control lines. This article mainly talks about the selection and use of control cables.

KVV is a connection line used for control and protection lines in industrial and mining enterprises, energy and transportation sectors, commonly known as control cables. Mainly used in cable trenches, pipelines, shafts and other fixed occasions with large mechanical tension.

Overview of control cables

Cables connected from the control center to various systems to transmit signals or control operating functions are collectively called control cables. The early functions of control cables were relatively simple, including: indicator light display, instrument indication, relay and switch cabinet operation, alarm interlock system, etc.

What are the considerations when choosing control cables?

1. Length: Length is the most intuitive identification method. You must choose one that meets national standards. .

2. Packaging: In addition to whether the packaging is exquisite and clear, what is more important is whether the manufacturer information, product specifications and model parameters are clear. Do not buy three-no products.

3. “CCC” certification: Control cables are national compulsory safety certification products. Regular products must have the “CCC” mark certified by the China Electrical Products Certification Commission. If not, they are not trustworthy.

4. Appearance: such as whether it is smooth and round, the color is uniform, the sheathed insulated conductor is tight and difficult to peel off, etc. If it is a counterfeit and inferior product, it will be rough in these aspects.

Precautions for installation and wiring of control cables

1. Under the eaves. Standard LAN cables can only be used if the control cables are not exposed to direct sunlight or extreme temperatures. It is recommended to use a catheter. Ultraviolet (UV) – Do not use cables without UV protection in direct sunlight.

2. On the exterior wall. Avoid direct sunlight on the wall and artificial damage. Heat – Cables get very hot inside metal ducts or trunking, and many polymeric materials will reduce their service life at these temperatures.

3. In the pipeline. If control cables are laid in pipelines, attention should be paid to damage to plastic pipes and heat conduction of metal pipes. Mechanical Damage (Repair Cost) – Fiber optic cables are very expensive to repair and require at least two terminations at each discontinuity.

4. Suspended applications/overhead cables. Consider cable sag and stress. Whether the cable is exposed to direct sunlight.

5. Laying directly in the underground cable trench, this environment has a small control range. The installation of cable trenches should be regularly checked for dryness or moisture levels. Grounding–If the control cable shield needs to be grounded, the appropriate standards must be followed.

6. Underground pipelines. In order to facilitate future upgrades, cable replacement and isolation from surface pressure and surrounding environment, auxiliary piping is a better method. But don’t count on the pipes staying dry forever, as this will affect the choice of cable type. Water – Moisture in twisted-pair LAN cables increases the capacitance of the cable, thereby lowering the impedance and causing near-end crosstalk problems.

Post categories

Most Popular Posts

-

The 136th Canton Fair welcomes you to participate!

October 12, 2024 -

High temperature cable introduction

July 26, 2024 -

Kenya Power and Energy Exhibition 2024

June 11, 2024 -

Introduction of rubber sheathed cable

June 5, 2024