- Offices Time:24 Hours Online

- Email:[email protected]

- WhatsApp:+8618339938759

Posted on February 21, 2023

How Much Is XLPE Insulated Power Cable?

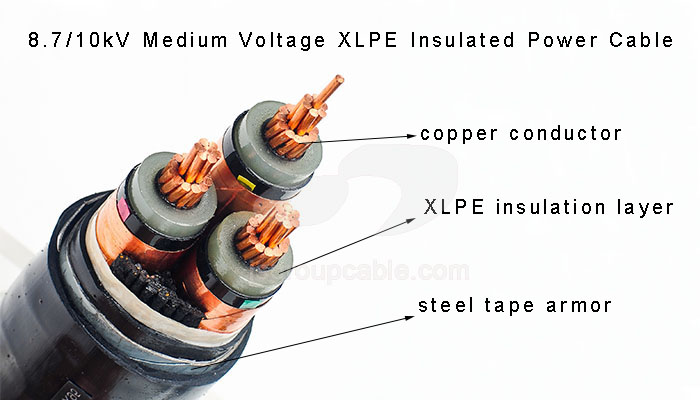

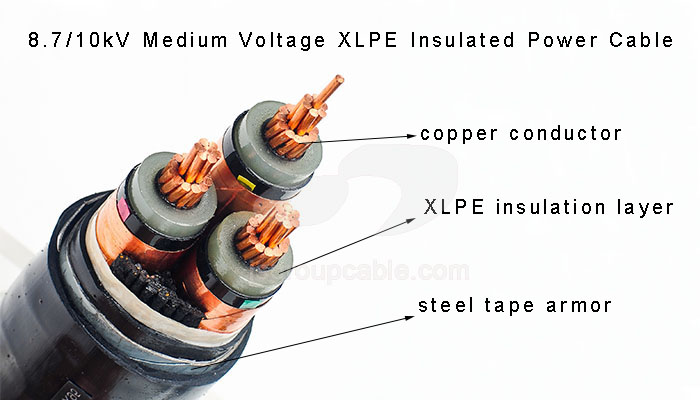

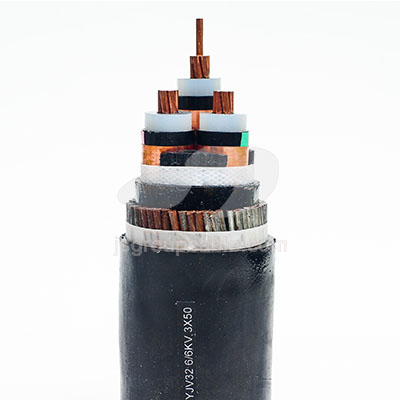

XLPE insulated power cable are a type of electrical cable commonly used for transmitting high voltage electrical power. Its typically made up of a conductor, an insulation layer of XLPE, and an outer sheath for protection. The insulation layer provides excellent electrical properties, including a high dielectric strength, low dielectric loss, and low capacitance.Compared to other types of cable insulation materials, XLPE is more durable and has a longer service life. It is also more resistant to water, chemicals, and UV radiation, which makes it suitable for use in harsh environments. XLPE insulated power cable are used in a variety of industries, including power generation, transmission, and distribution, as well as in industrial applications such as mining, petrochemical, and construction.

XLPE insulated power cable has so many excellent performances, so what is its price?

The cost of XLPE insulated power cable can vary depending on a number of factors such as the cable length, the voltage rating, the conductor size, the insulation thickness, and the manufacturing brand.

In general, XLPE insulated power cable tends to be more expensive than other types of cables due to its advanced properties and performance characteristics. However, the actual price will depend on the specific requirements of the project and the supplier you choose.To get a more accurate cost estimate, it’s best to contact a cable manufacturer or distributor and provide them with your specific requirements. They can then provide you with a customized quote based on your needs.

The price of XLPE insulated power cable also varies by region and country. The cost in one country may be significantly different from that in another country due to factors such as manufacturing costs, transportation costs, taxes, and import/export duties.

In general, XLPE insulated power cables with higher voltage ratings and larger conductor sizes tend to be more expensive than those with lower voltage ratings and smaller conductor sizes.

As of my knowledge, the price of a standard 3-core XLPE insulated power cable with a voltage rating of 11 kV and a conductor size of 95 mm2 can range from $5 to $10 per meter. However, this is just a general estimate, and the actual price may be higher or lower depending on the specific requirements and market conditions.

It’s important to note that while cost is an important factor in cable selection, it should not be the only factor considered. Other important factors such as cable performance, reliability, and safety should also be taken into account when selecting an XLPE insulated power cable for your project.

Additionally, the cost of XLPE insulated power cable may be influenced by the brand of the manufacturer or supplier. Some brands may be more well-known or have a reputation for high quality and reliable products, which may result in a higher price point.

The length of the cable also plays a significant role in determining the cost. Longer cables will generally cost more than shorter cables due to the increased materials and manufacturing costs, as well as transportation and installation expenses.

However, it’s important to balance the cost of the cable with the overall cost of the project. While a cheaper cable may save money in the short term, it may end up costing more in the long run if it fails prematurely or doesn’t perform as expected. Therefore, it’s important to choose a cable that meets the performance and reliability requirements of the project, regardless of the cost.

In summary, the cost of XLPE insulated power cable can vary depending on a range of factors, including voltage rating, conductor size, insulation thickness, manufacturing brand, and regional market conditions. It’s important to choose a cable that meets the performance and reliability requirements of the project, while also considering the overall cost and manufacturer’s warranty and after-sales support.

Another important factor that can impact the cost of XLPE insulated power cable is the type of installation environment. For example, cables installed in harsh environments such as offshore or underground may require additional protection or special coatings to prevent damage from moisture, corrosion, or other external factors. This can result in a higher cost compared to cables installed in more benign environments.

In addition to the cost of the cable itself, it’s important to factor in the cost of accessories and installation. This includes items such as cable glands, termination kits, and jointing kits, which are necessary to ensure a safe and secure connection. Installation costs may also vary depending on the complexity of the installation and the level of expertise required.

Overall, the cost of XLPE insulated power cable is determined by a variety of factors, and it’s important to carefully consider all of these factors when making a decision. By working with a reputable supplier and considering the overall needs and requirements of the project, it’s possible to select a high-quality, reliable cable that meets the project’s performance and budgetary needs.

Why is XLPE Insulated Power Cable more expensive?

XLPE insulated power cable are generally more expensive than other types of power cables due to a variety of reasons:

1.Raw Material Cost

XLPE insulated power cable are made using high-quality, cross-linked polyethylene materials which are more expensive than the materials used in other types of cables.

2.Manufacturing Process

The manufacturing process for XLPE insulated power cable is more complex and requires specialized equipment and skilled labor. This increases the cost of production and makes them more expensive than other types of cables.

3.Performance and Durability

XLPE insulated power cable offer superior performance and durability compared to other types of cables. They can handle higher temperatures, have a longer lifespan, and are more resistant to environmental factors such as moisture and abrasion. This added performance and durability also contributes to their higher cost.

4.Testing and Certification

XLPE insulated power cable must go through rigorous testing and certification processes to ensure they meet strict safety and performance standards. These testing and certification processes add to the overall cost of the cable.

How to buy XLPE insulated power cable?

Finally, it’s important to consider the overall project budget and timeline when selecting an XLPE insulated power cable. While it may be tempting to select a cheaper option to save costs, it’s important to balance this with the overall needs and requirements of the project. A high-quality, reliable cable may ultimately prove more cost-effective in the long run, as it can reduce the risk of downtime, repairs, and replacement.

When purchasing XLPE insulated power cable, it’s also important to consider the manufacturer’s warranty and after-sales support. A reputable supplier will typically offer a warranty on their products, which can provide peace of mind and protection against manufacturing defects or premature failure.

While XLPE insulated power cable may be more expensive than other types of cables, they offer significant benefits in terms of performance, durability, and safety. Therefore, they are a worthwhile investment for many industries that require reliable and high-performance power transmission.

Post categories

Most Popular Posts

-

The 136th Canton Fair welcomes you to participate!

October 12, 2024 -

High temperature cable introduction

July 26, 2024 -

Kenya Power and Energy Exhibition 2024

June 11, 2024 -

Introduction of rubber sheathed cable

June 5, 2024