- Offices Time:24 Hours Online

- Email:[email protected]

- WhatsApp:+8618339938759

Posted on February 17, 2023

Detailed introduction of triplex overhead wire

Triplex overhead wire is a type of electrical transmission line used to transmit power in three phases. Its commonly used in electrical power distribution systems, particularly for overhead power lines that run along streets and highways. They are also used in some railway electrification systems to supply power to trains.

Compared to single-phase overhead wires, triplex overhead wires can carry more power with less voltage drop over long distances. They are also more reliable and efficient, as they can better balance the load among the three phases. However, triplex overhead wires are more expensive to install and maintain than single-phase wires due to the additional wire and hardware required.

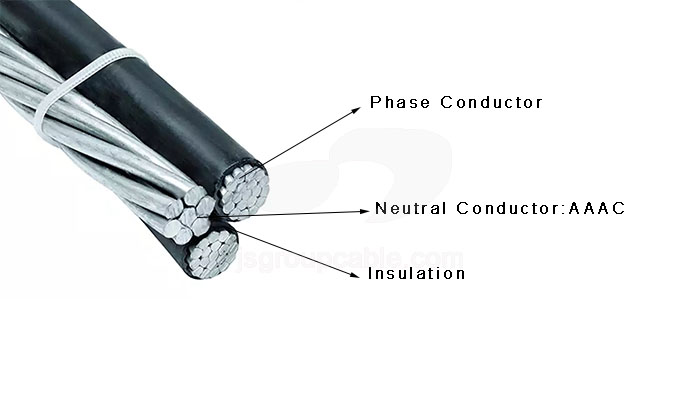

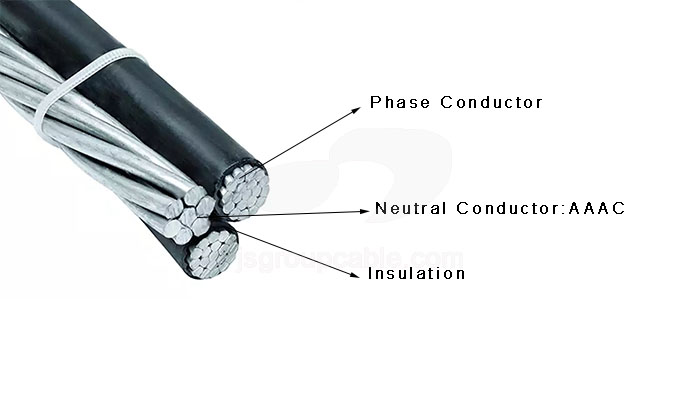

Structure of triplex overhead wire

Triplex overhead wire consists of three wires, one for each phase, arranged in a triangular configuration with a neutral wire placed in the center. The three phase wires carry alternating current (AC) power, while the neutral wire is used for grounding and to balance the loads.two of which are aluminum alloy and one is a steel support cable. The steel cable provides mechanical support to the aluminum conductors and prevents sagging.

The triplex overhead wire is typically designed with the steel support cable placed in the center, with the two aluminum conductors wrapped around it in a helical pattern. The steel support cable is usually made of galvanized steel, while the aluminum conductors are made of an aluminum alloy that is lightweight and has good electrical conductivity.

The diameter of the aluminum conductors is usually larger than that of the steel cable, which helps to balance the tension in the line and prevent sagging. The steel cable is also designed to have a higher breaking strength than the aluminum conductors, which helps to prevent the line from snapping under heavy loads or high winds.

The triplex overhead wire is commonly used for residential power distribution, where it is strung between utility poles or other structures. It is also used in rural areas and for industrial power distribution, where the longer spans require more robust and durable overhead lines.

The three conductors are typically made of the following materials:

Aluminum: The outer two conductors are usually made of aluminum, which is a lightweight, low-cost metal that is a good conductor of electricity.

Steel: The center conductor is made of steel, which is a strong and durable metal that provides mechanical support for the cable.

The combination of aluminum and steel in the triplex wire makes it strong and lightweight, which makes it well-suited for use in overhead power distribution. The aluminum conductors provide good electrical conductivity, while the steel core provides strength and durability.

In some cases, the aluminum conductors may be coated with a layer of zinc to improve their corrosion resistance. This is known as galvanized triplex wire.

The key features of a triplex overhead wire

Three Conductors

As the name suggests, a triplex overhead wire consists of three conductors bundled together. This allows for the transmission of three-phase power, which is commonly used in high voltage power transmission and distribution systems.

Bundled Design

The three conductors are typically bundled together using a specially designed spacer, which helps maintain a consistent spacing between the conductors while also providing support for the weight of the cables.

Insulated Phase Conductors

The two phase conductors in a triplex overhead wire are typically insulated to prevent electrical arcing and minimize the risk of electrocution. The insulation may be made of a variety of materials, including rubber, PVC, or polyethylene.

Bare Neutral Wire

The neutral wire in a triplex overhead wire is usually left bare, meaning it does not have any insulation. This is because the neutral wire typically carries less current than the phase conductors, and the risk of electrocution or electrical arcing is lower.

High Voltage

Triplex overhead wires are typically used in high voltage power transmission and distribution systems, where the voltage can range from a few thousand volts to several hundred thousand volts.

Weather Resistance

Triplex overhead wires are designed to withstand a range of weather conditions, including wind, rain, snow, and ice. The conductors are typically made of aluminum or copper, which are both highly conductive and resistant to corrosion. The bundled design also helps reduce the impact of wind on the cables.

The laying method of triplex overhead wire

The first step is to install the support structure for the overhead wire. This is usually done by erecting wooden or metal poles at regular intervals along the route where the wire is to be laid.

Next, the wire is attached to the support structure. The two outer conductors are attached to the top of the pole, while the center conductor is attached to the bottom.

The wire is then pulled tight and secured to the pole using clamps or other fasteners.

If the distance between two poles is too long, a sagging effect may occur in the center conductor due to gravity. To prevent this, a suspension clamp is used to support the center conductor at intervals along the span between the poles.

Once the wire has been installed and secured to the support structure, it is connected to a transformer or other electrical equipment at both ends of the line.

Finally, the line is tested to ensure that it is working properly and that there are no faults or other problems that could cause power outages or other issues.

Overall, the laying method of triplex overhead wire is relatively straightforward and can be completed quickly and efficiently, making it a popular choice for distributing power in residential areas. However, it is important to follow proper safety procedures and to use high-quality materials to ensure that the wire is safe and reliable for long-term use.

Post categories

Most Popular Posts

-

The 136th Canton Fair welcomes you to participate!

October 12, 2024 -

High temperature cable introduction

July 26, 2024 -

Kenya Power and Energy Exhibition 2024

June 11, 2024 -

Introduction of rubber sheathed cable

June 5, 2024