- Offices Time:24 Hours Online

- Email:[email protected]

- WhatsApp:+8618339938759

Posted on September 16, 2022

Common specifications and models of Aerial Bundled Cable

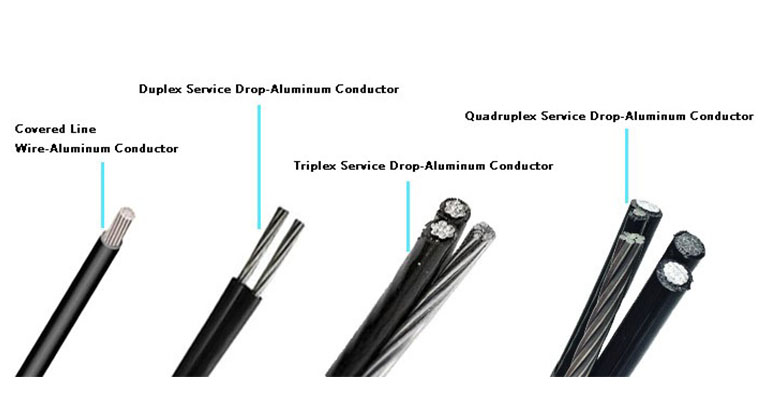

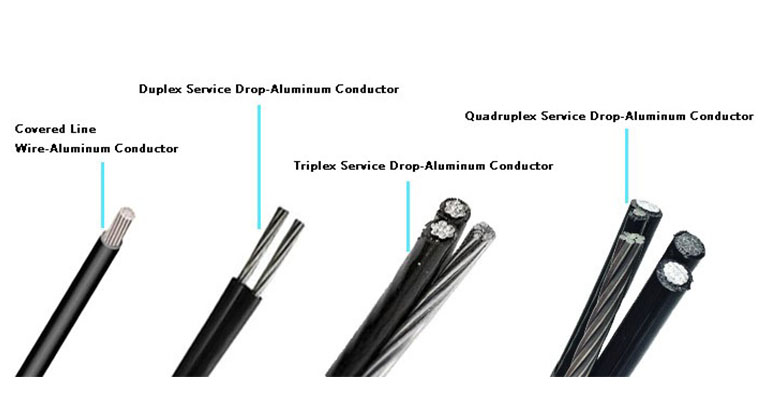

Aerial cables are a very common wire in our daily life. Generally used in some open and high places in the city, overhead cables are used on common utility poles, and the production and use costs of overhead cables are relatively low. So, what are the common specifications and models of overhead cables? What should be considered when using overhead cables?

Common specifications and models of overhead cables

1.JKV JKLV JKY JKLY JKYJ JKLYJ copper, aluminum core PVC insulated overhead cable, copper aluminum core polyethylene insulated overhead cable copper, aluminum core XLPE insulated overhead cable, used for overhead fixed laying of lead wires, etc.

2.JKYJ JKLYJ JKTRYJ JKY JKLY JKTRY JKGYJ JKLGYJ copper, aluminum XLPE insulated overhead cable, soft copper core XLPE insulated overhead cable, copper, aluminum core polyethylene insulated overhead cable, soft copper core polyethylene insulated overhead cable , Copper core stranded XLPE insulated overhead cables, aluminum core stranded XLPE insulated overhead cables, used for fixed overhead laying, soft copper core products for transformer down-conductors. When the cable is overhead, it should be considered to keep a certain distance between the cable and the tree. When the cable travels far, the cable and the tree are allowed to contact frequently. Steel core type overhead cables are used for laying across mountains and rivers.

3.JKLY/B aluminum core natural color XLPE insulated overhead cable, when used for overhead fixed laying cable erection, should consider keeping a certain distance between the cable and the tree; when the cable is running, the cable and the tree are allowed to be in frequent contact.

4.JKLYJ/QJKLY/Q Aluminum Core Light XLPE Insulated Overhead Cable Aluminum Core Lightweight Polyethylene Insulated Overhead Cable is used for overhead fixed laying of cables. When erecting cables, a certain distance between cables and trees should be considered; when cables are running, cables and trees are allowed. short-term contact.

Use steel core aluminum stranded conductor XLPE insulated overhead insulated cable (model JKLGYJ-1, 1X10/2), the vertical pole span can be 20 meters, JKLGYJ-11X10/2 long-term allowable current carrying capacity is 75A, considering the long distance Line loss, but enough. Pay attention to whether the local power supply voltage is high or not. If it is relatively low, consider using JKLGYJ-1, 1X16/3 (refer to the current carrying capacity of 100A), mainly considering that the line loss of the aluminum core wire is larger. In the laying process, the technical parameters of the overhead cable should also be considered.

What should be considered when laying overhead cables

1.Cable laying and installation should be carried out by qualified professional units or professionals. If the construction and installation do not meet the requirements of relevant specifications, the cable system may not operate normally.

2.Overhead cable laying is a different method than traditional buried cable laying. Due to special reasons such as the influence of other underground pipelines in the city or the influence of municipal public facilities, when the cables cannot be laid underground or general overhead lines are used, overhead cables can be used.

3.When laying cables manually, the command and control rhythm should be unified. Every 1.5 to 3 meters, one person should carry the cable on his shoulder, pull it while laying it down, and release it slowly.

4.When the overhead cable is led down from the pole into the ground, a 2.5m-long protective pipe should be used on the ground and fixed firmly. The root of the protective pipe should be extended into the ground for 0.2m.

5.Before laying the cable, check the appearance of the cable and whether the head is in good condition. When laying, pay attention to the rotation direction of the cable reel, and do not flatten or scratch the outer sheath of the cable. Do not use low-temperature beating to straighten the cable in winter to avoid cracking of the insulation and sheath.

6.If the cable is directly buried, pay attention to the soil conditions. The buried depth of cables under buildings should generally not be less than 0.3m. If the surrounding environment is soft or complicated, such as farmland, construction sites or roads, etc., there should be a certain buried depth (0.7 ~ 1m) to prevent direct buried cables from being accidentally damaged. If necessary, prominent signs should be erected.

The so-called overhead cable is relative to the cable, that is, the line in which the conductor is erected at a certain height by the tower to transmit electric energy. The ground-to-ground insulation of overhead cables in high-voltage transmission and distribution networks generally relies on air. The previous distribution lines (10kV except 380V) generally use bare conductors. However, due to the complex distribution environment in urban areas, short-circuit grounding and lightning strike lines often occur. Therefore, at present, overhead cables below 10kV generally use insulated conductors (that is, the outer layer of the conductor is wrapped with an insulating layer), which is the so-called insulated overhead cable.

Aerial cables are divided into low voltage and high voltage. Generally, there are many types. For example, for street lamp overhead cables, JKLYJ*10KVA*50*100, which indicates the voltage, model, material, core cross-sectional area and length of the overhead cable.

Post categories

Most Popular Posts

-

The 136th Canton Fair welcomes you to participate!

October 12, 2024 -

High temperature cable introduction

July 26, 2024 -

Kenya Power and Energy Exhibition 2024

June 11, 2024 -

Introduction of rubber sheathed cable

June 5, 2024