- Offices Time:24 Hours Online

- Email:[email protected]

- WhatsApp:+8618339938759

Posted on February 8, 2023

Classification of flame retardant cables

In recent years, in the global power system fire accidents, the proportion of power supply interruptions caused by power cables has a clear upward trend. Therefore, flame-retardant cables are used to prevent the spread of fire in places where there are a large number of electrical equipment and a large number of cables are densely laid, such as power plants and substations, and fire-resistant cables are used to ensure important circuits. However, some electrical designers are unclear about the concept of natural cables and fire-resistant cables, and do not know the structure and characteristics of the two, which leads to the inability to correctly select these two cables according to the power supply requirements. Therefore, a comprehensive understanding of flame-retardant cables and fire-resistant cables is the first condition for correct selection of them. Today, let’s take a closer look at flame retardant cables.

flame retardant cable

Flame retardant cable means that under the specified test conditions and environment, the sample is burned, and after the fire source is removed, the spread of the flame is within the specified range, and it can be automatically extinguished within a limited time. Its fundamental feature is that it can prevent the spread of fire when a fire occurs, limit the loss within a certain range, and reduce the loss of equipment on the fire scene.

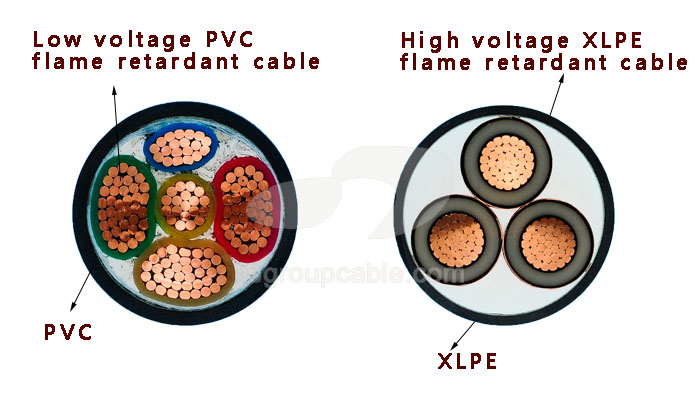

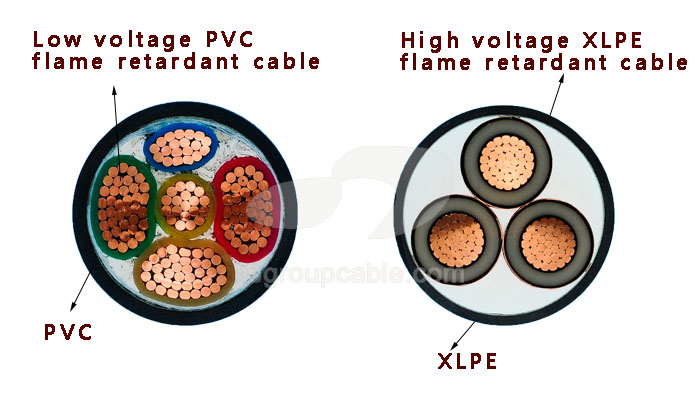

Structural characteristics of flame retardant cables

The structure of the flame retardant cable is basically the same as that of the ordinary cable, the difference is that its insulation layer, sheath layer, outer sheath and auxiliary materials are all made of flame retardant materials.

Classification of flame retardant cables

According to the difference of cable flame-retardant materials, flame-retardant cables are divided into two categories: halogen-containing flame-retardant cables and halogen-free low-smoke flame-retardant cables.

The insulation layer, sheath layer, outer sheath and auxiliary materials of halogen-containing flame-retardant cables are all made of halogen-containing polyethylene flame-retardant materials, so they have good flame-retardant properties. However, when the cable burns, it will release a large amount of dense smoke and halogen acid gas. The halogen acid gas is corrosive to the surrounding electrical equipment. When a fire occurs, rescuers need to wear gas masks to approach the scene to extinguish the fire. When the cable burns, it will cause harm to the surrounding electrical equipment and rescue personnel, which is not conducive to the fire fighting and rescue work, resulting in serious “secondary hazards”.

The insulation layer, sheath layer, outer sheath and auxiliary materials of halogen-free low-smoke flame-retardant cables are all or partly made of halogen-free cross-linked polyethylene flame-retardant materials, which not only have better flame-retardant properties, but also When the cable burns, no halogen acid gas is released, and the amount of smoke generated by the cable is also small. Its halogen content is about one-third of that of halogen-containing flame-retardant cables, and its smoke generation is also close to the recognized low-smoke level.

Precautions for selection of flame retardant cables

Designers should design, select and install flame-retardant cables according to the specific characteristics of flame-retardant cables, and should pay attention to the following issues:

1.Since the halogen-containing flame-retardant cable will release corrosive gas when burning, it will greatly hinder the fire-fighting work. Therefore, in public places with high density of people, halogen-free low-smoke flame-retardant cables should be used as much as possible. Any kind of flame retardant cable can be used in places with low population density.

2.Flame-retardant cables are divided into three types: A, B, and C. Among them, class A flame-retardant cables have better performance and relatively more expensive prices. When selecting, you should pay attention to the type of flame-retardant cables.

3.It is impossible to distinguish the type of flame-retardant cable from the appearance, and only rely on the flame-retardant cable manufacturer to guarantee the supply, so the cable manufacturer should be carefully selected in the design and selection.

4.Compared with halogen-containing flame-retardant cables, halogen-free low-smoke flame-retardant cables have the characteristics of low corrosion and low smoke, but their electrical and mechanical properties are significantly reduced. Therefore, when laying cables, halogen-free low-smoke flame-retardant Cables should have a larger bending radius than halogen-containing flame-retardant cables.

5.When designing cable laying, it is not suitable to lay non-flame retardant cables and flame retardant cables side by side, and it is not suitable to lay flame retardant cables of different flame retardant categories side by side.

Post categories

Most Popular Posts

-

The 136th Canton Fair welcomes you to participate!

October 12, 2024 -

High temperature cable introduction

July 26, 2024 -

Kenya Power and Energy Exhibition 2024

June 11, 2024 -

Introduction of rubber sheathed cable

June 5, 2024