- Offices Time:24 Hours Online

- Email:[email protected]

- WhatsApp:+8618339938759

Posted on October 25, 2022

Characteristics and functions of control cables

With the continuous and rapid economic growth, it has provided a huge market space for cable products. Due to the strong temptation of the market, the world has focused its attention on the Chinese market. In the short decades of reform and opening up, China’s cable manufacturing industry The huge production capacity formed by the industry has impressed the world.

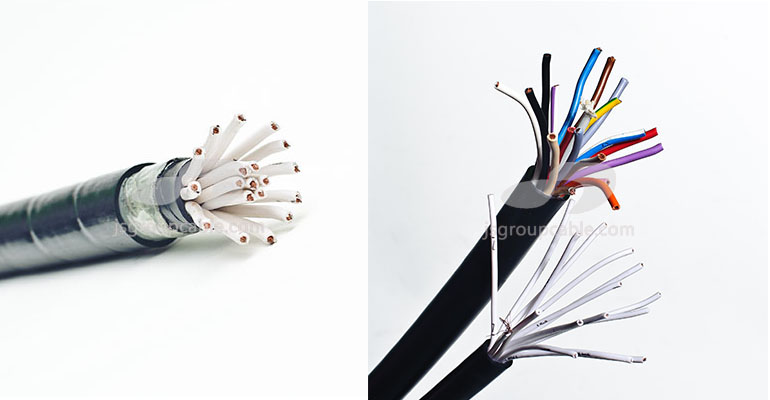

1.Control cable structure

Multi-layer insulation, PP filler and non-magnetic steel shielding armor. The copper conductors of the control cables are wrapped with PVC insulation, and the PP filler is filled in the PP wrap. Between this layer and the PVC insulating layer, a non-magnetic steel shielding armor layer is arranged on the outer layer of the PP wrap, and the non-magnetic steel shielding armor layer is wrapped with a PVC sheath layer. Compared with traditional cables, control cables have fewer processes, high production efficiency, and can be continuously produced. The control cable can be shielded from external interference, but also can be armored to protect the inner insulating core.

2.The role of the control cable

The purpose of cable manufacturers adding armor on control cables is not only to improve tensile strength, compressive strength and other mechanical protection to prolong service life, but also to improve the anti-interference performance of the cable through shielding protection.

The commonly used materials for control cable armor are steel tape, steel wire, aluminum tape, aluminum tube, etc. Among them, steel tape and steel wire are widely used, because steel tape and steel wire are not only cheap but also of good quality, have high magnetic permeability, and have Good magnetic shielding effect, can be used for anti-low frequency interference, no need to pass pipes during installation, and the armored cable can be directly buried and laid.

The mechanical protection layer of the control cable can increase the mechanical lightness and corrosion resistance of the cable, and is widely used in all structures of the cable. The envoy design of the control cable makes it suitable for use in areas prone to mechanical damage and corrosion. Control cables are laid in a variety of ways and can be laid in rocky areas.

The more popular control cables are also buried wires and cables. Armouring of control cables can enhance tensile strength, compressive strength and other mechanical protection for longer service life. The armored cable has anti-external force performance, can also prevent mice from being bitten, and will not cause power transmission problems through the armor. The bending radius of the armor should be large, and the armor layer can be grounded to protect the cable.

3.Use characteristics of control cables

(1) Control cables are used for monitoring circuits and protection circuits. The AC rated voltage Uo/U is specified as 0.6/1kV and below.

(2) Rated voltage Uo/U of control cable: 450/750V, 0.6/1kV.

(3) The working temperature of the control cable: the working temperature of the ordinary type does not exceed 70℃: the working temperature of the cross-linked polyethylene does not exceed 90℃.

(4) The bending radius of the control cable is small: the unarmored cable should not be less than 6 times the outer diameter of the cable; the cable with the armored or copper tape shielding structure should not be less than 12 times the outer diameter of the cable; the flexible cable with the shielding structure should be Not less than 6 times the outer diameter of the cable.

4.Maintenance of control cables

Common faults in control cable lines include mechanical damage, insulation damage, insulation damp, insulation aging and deterioration, overvoltage, and cable overheating faults. When the above fault occurs in the line, the power supply of the faulty cable should be cut off, the fault point should be found, the fault should be checked and analyzed, and then repaired and tested.

Post categories

Most Popular Posts

-

The 136th Canton Fair welcomes you to participate!

October 12, 2024 -

High temperature cable introduction

July 26, 2024 -

Kenya Power and Energy Exhibition 2024

June 11, 2024 -

Introduction of rubber sheathed cable

June 5, 2024