- Offices Time:24 Hours Online

- Email:[email protected]

- WhatsApp:+8618339938759

Posted on December 16, 2022

The structure and application of 35kV single core high voltage cable

With the development of urbanization, there are more and more high-voltage long-distance cable projects. Since the three-core high-voltage cables cannot be made too long, there must be multiple cable intermediate joints in the line, which brings many safety hazards to the power transmission system. . Compared with the three-core cable, the single-core high-voltage cable shows incomparable advantages in its single length, laying process and cable head production. Therefore, single-core cables are mostly used in long-distance transmission lines.

High-voltage single-core cable means that there is only one conductor in an insulating layer. When the voltage exceeds 35kV, most lines will choose to use single-core cables. The relationship between the core and the metal shielding layer can be regarded as the relationship between the coil and the iron core in the primary winding of a transformer.

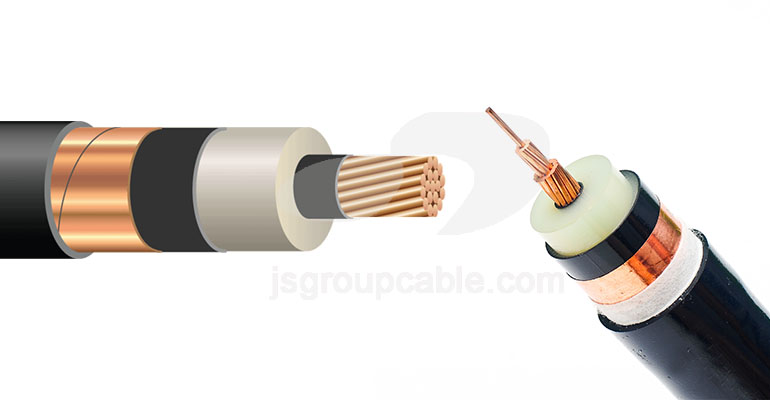

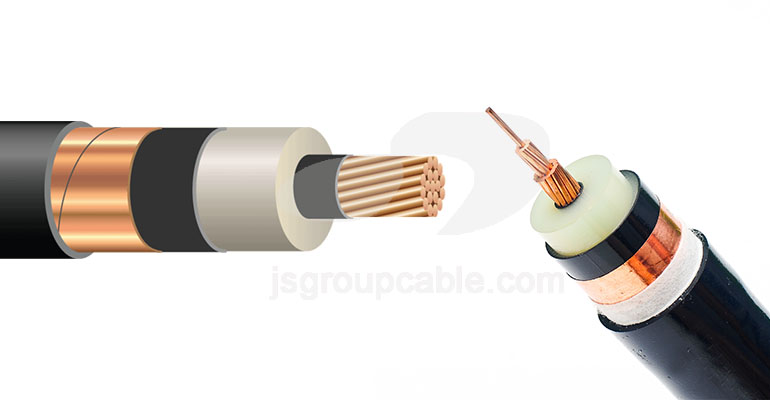

1.The structure of 35kV Single Core High Voltage Cable

(1) Conductor: The number of wire cores is mostly single core, two cores, three cores, four cores, and five cores. According to the number of wire cores, the wires are pressed into circular, semicircular, fan-shaped and other shapes.

(2) Shielding layer: The shielding layer refers to the component that isolates the electromagnetic field and the external electromagnetic field in Jiangyizhong cable products. Some cable products also need to be shielded and isolated from each other before they are in different phases. It can be said that the shielding layer is a kind of “Electromagnetic isolation screen”, conductor shielding and insulation shielding of high-voltage cables are used to homogenize the distribution of the electric field.

(3) Protective layer: In order to protect the cable from the intrusion of foreign substances and prevent damage from external forces. The protective layer is mainly composed of inner lining layer, armor layer and outer sheath.

2.Special precautions for 35kV Single Core High Voltage Cable

(1) The cable should be unarmored or armored with non-magnetic material. To avoid circulating currents, the metal shield should be grounded at one point only.

(2) All wires in the same circuit should be placed in the same pipe, conduit or trunking, or wire clamps should be used to install and fix all phase wires together, unless they are made of non-magnetic materials.

(3) When installing two, three or four single-core cables, a single-phase circuit, a three-phase circuit or a three-phase and neutral circuit will be formed respectively. In this case, the cables should be in contact with each other as much as possible. In all cases the distance between the sheaths of two adjacent cables shall be less than the diameter of one cable.

(4) When a single-core cable with a rated current greater than 250A must be installed close to the steel cargo tank wall, the clearance between the cable and the tank arm is to be at least 50 mm. Except for cables belonging to the same AC circuit laid in a trefoil.

(5) Magnetic materials cannot be used between the single-core cables of the same group. When the cables pass through the steel plate, all the wires of the same circuit should pass through the steel plate or filler together, so that there is no magnetic material between the cables. And the gap between the cable and the magnetic material should be greater than 75mm.

(6) In order to make the impedance of the three-phase circuit of a considerable length composed of single-core cables with a conductor cross-section equal to or greater than 185mm² approximately equal, each phase should be transposed once at a gap of no more than 15m. Alternatively, the cables can be laid in a trefoil. When the laying length of the cable is less than 30m, it is not necessary to take the above measures.

(7) When several single-core cables are used in parallel in each phase of the line, all cables should have the same path and equal cross-section. And the cables belonging to the same phase should be laid alternately with the cables of other phases to avoid uneven distribution of current.

When the single-core cable passes through the current, the metal sheath generates an induced voltage, which is proportional to the length of the cable line and the current flowing through the core. If both ends of the sheath are grounded, the side sheath and the wire will form a closed loop. The circular current on the metal sheath will form a high induced voltage on the shield when a short circuit fault occurs on the line, an operating overvoltage or a lightning strike occurs. It may even break down the sheath insulation. At this time, if the two ends of the metal sheath are still connected to each other, the metal sheath will appear

There is a large circulating current, causing eddy current loss, causing a large current to pass through the metal sheath of the cable, causing heat, and accelerating the aging of the cable insulation. Long-term operation will burn the insulation layer of the cable, resulting in failure.

The grounding of single-core cables usually adopts four methods: direct grounding at both ends of the metal sheath, grounding at one end, protective grounding at both ends of the midpoint grounding, and grounding at both ends of the cross-connection.

Post categories

Most Popular Posts

-

The 136th Canton Fair welcomes you to participate!

October 12, 2024 -

High temperature cable introduction

July 26, 2024 -

Kenya Power and Energy Exhibition 2024

June 11, 2024 -

Introduction of rubber sheathed cable

June 5, 2024